1

Provide You with the Best Plastic Container Mold Solutions

Leading Plastic Container Mold Manufacturer

Find the best plastic container molds with us

Hing Tung has always been a reliable custom plastic mold manufacturer, deeply trusted by overseas small and medium-sized enterprises, providing customized mold services to automobile, home furnishing, toys, industrial and other industries. For businesses that need custom plastic container molds, Hing Tung is your first choice.

Customized Different Types of Plastic Container Molds

Hing Tung has expertise in the field of plastic containers, but we have the ability to produce plastic container molds of almost any size. Not only that, Hing Tung also provides molding service of junction plastic containers.

For many years, we have been providing high quality plastic container molds to our customers. Help them improve work efficiency and produce higher quality plastic container products.

Whatever your requirements, we can provide the right injection molding process and equipment to set your product apart from the competition. Services range from engineering and design to final assembly, decoration and shipping. Hing Tung is your single source for entire projects and complex components. Our portfolio of in-house services can help you simplify your supply chain, reduce costs and shorten lead times. Contact us today to discuss your tooling needs.

Fruit Storage Container Mold

Plastic Box Mould

Plastic Tableware Container Mold

Pastry Container Mold

Storage Container Mold

Plastic Foldable Container Mould

Our Customization Services for Plastic Container Molds

Package Delivery

Hing Tung uses premium packaging to protect your Plastic Container Mold products until they are delivered safely to your doorstep.

Plastic Container Mold Details

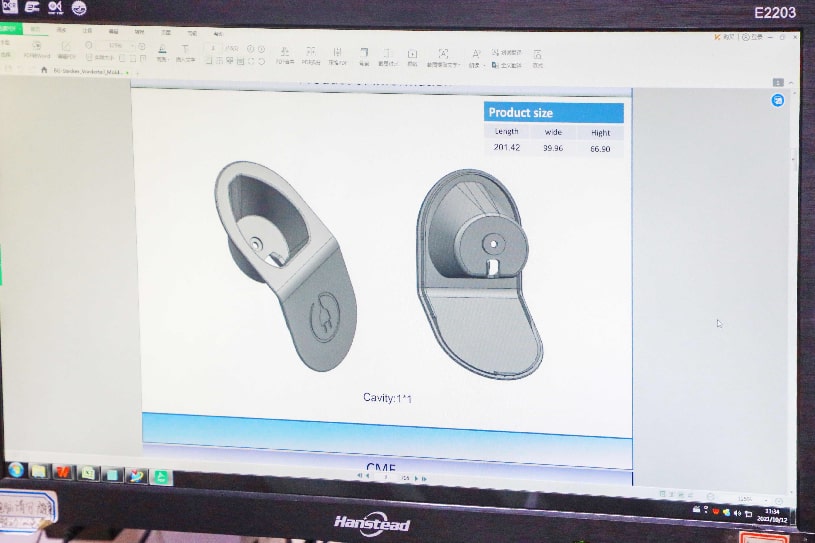

| Product name | Plastic Thin Wall Container Mold Moulds |

|---|---|

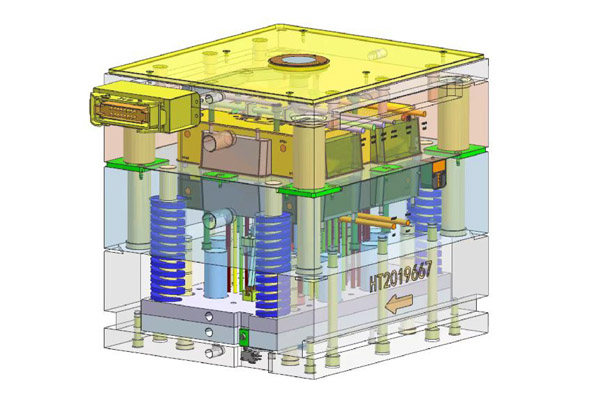

| Core and Cavity steel | 2344, H13, NAK80, S136….. |

| Mould base | P20, 45# etc |

| No.cavities | 1,2,4,6 |

| Sprue type: | Hot runner, Cold runner, |

| Gate: | pin point gate, valve gate |

| Design software | UG, PROE, CAD, Solidwork ect. |

| Plastic material | PP, ect. |

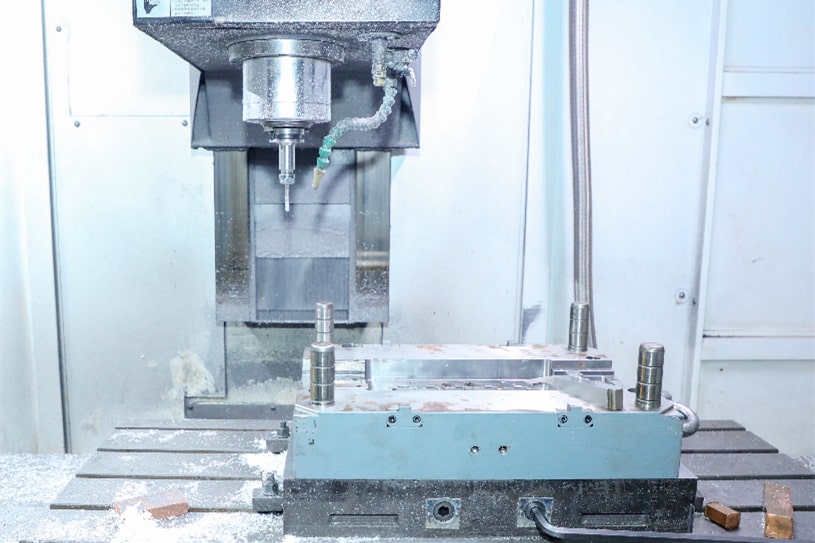

| Main process | Milling, grinding, drilling, engraving, borning, polishing--- |

| Surface treatment | mirror polish ,or textured surface |

| Mould testing | according to the customer's machine tonnage |

| Packaging | Wooden Cases |

| Mould life | 3,000,000 shots |

| Delivery time | 45-50 days |

| Payment Terms | T/T, western union or L/C |

| Transportation | By Sea or by air |

| Specification | Depends on customer's requirements. |

| OEM order | Welcome |

Custom Plastic Container Molds Designed by Experts

We understand that each customer is unique and that you may require a plastic container specially designed to meet your application. Therefore, we provide a full range of custom mold services. These services include:

- Customized shape and size

- Color customization

- Unique mold design

Our plastic container mold design team are experienced professionals who have been involved in countless projects. In-depth knowledge of the plastic container mold manufacturing process enables them to handle any custom request with ease. All you have to do is let us know the type of plastic container you need and we will design and produce it for you.

Plastic Container Molds: 2023 FAQ Guide

If you plan to customize or source plastic container moulds, then you may encounter various problems. To better understand plastic container moulds, please read the following FAQ guide, designed to answer your questions.

1. What is Plastic Container Mold?

Plastic container molds, also referred to simply as container molds, are made by injection molding, in which molten plastic is injected into a container-shaped mold. Plastic Container Molds are used to manufacture containers of different shapes, sizes and dimensions that can be used for a variety of purposes such as storage, packaging, shipping, and more. Plastic container molds are crucial in manufacturing because container molds are made using different plastic materials depending on their usage. Plastic offers great flexibility and resistance to damage.

2. What is the best plastic for plastic container molding?

The best plastic depends on the specific requirements and intended use of the container. The materials commonly used to form plastic container products are: polyethylene (PE), polypropylene (PP), polystyrene (PS), polyethylene terephthalate (PET), polyvinyl chloride (PVC), poly Carbonate (PC), Acrylonitrile-Butadiene-Styrene (ABS), Modified Polyethylene Terephthalate (PETG)

3. What is the service life of plastic container mold?

Plastic injection molds last from hundreds to over a million cycles. The life of an injection mold depends on its environment, maintenance, structure, type of plastic material used, molding process conditions, and other factors.

4. What is the most commonly used plastic container mold type?

The choice of plastic container mold type can vary widely depending on the specific requirements of the containers being produced and the industry in which they are used. However, one of the most commonly used types of plastic container molds is the injection mold.

5. What are the applications of plastic container molds?

Plastic container molds manufactured by Hing Tung have the following applications.

● Food packaging: they provide hygienic and lightweight solutions for food storage and transport.

● Beverage Packaging: Plastic molds are used to make bottles and containers for beverages such as water, soft drinks, juices and alcoholic beverages.

● Medical and Pharmaceutical: Containers used in the manufacture of pharmaceuticals, tablets, vials, syringes and medical devices.

● Household Goods: Includes storage containers, trash cans, laundry baskets and cleaning supply containers.

● Transportation and Logistics: Includes palletized boxes and bulk containers used to transport, store and transport goods in logistics and supply chain operations.

6. Does Hing Tung provide customized solutions for plastic container molds?

Our extensive customization capabilities give you the freedom to create unique plastic container solutions tailored to your target market. Just provide us with the exact dimensions and uses your project requires and our skilled team will bring it to life.

Once customers provide us with the necessary information about their products, our skilled team helps them get what they want. You can order customized products and we will ship them to you within a few weeks depending on the order quantity.

7. How many container molds does Hing Tung provide?

Hing Tung takes care of customer budgets and allows minimum order quantity service. Customers can order less quantity to meet their satisfaction or meet their budget. These unique services of Hing Tung set us apart from other manufacturers. We share a bond of trust with our clients.

8. How to order plastic container mold from Hing Tung?

You can place an order at Hing Tung in three easy steps.

1. open the Web page

2. Click the "Contact Us" button

3. Get an instant quote to place your order.

Our customer service staff adhere to a strict code of conduct and treat customers with the utmost courtesy. We are here 7 days a week to provide solutions to your queries

9. Why Choose Hing Tung's Plastic Container Mold?

Hing Tung is a leading manufacturer of high quality plastic container moulds. With years of industry experience, Hing Tung is committed to providing customers with cutting-edge technology and innovative solutions. No matter what type of container mold you need, we can provide it for you. And we also provide excellent customer support and service. Our in-house team of experts is available to answer any questions and provide assistance to keep your machinery running at its best.