Cable Tie Mould

Provide You with the Best Cable Tie Mould Solutions

Leading Cable Tie Mould Manufacturer

Find the best cable tie moulds with us

Hing Tung Plastic Mold Co., Ltd. has been producing cable tie molds since 2011. Due to rich experience, we produce cable tie molds with good quality and more competitive price. The cable tie molds we manufacture are made of durable high-quality material to ensure their long-lasting use. In addition, the mold is easy to operate, and the produced cable ties have high precision and stable quality. This makes it the tool of choice for making plastic cable ties. As a leading cable tie mold manufacturer in China, we will do our best to save costs for our customers. Regardless of mold steel, runner system, etc. If you need custom plastic cable tie mould. Contact us now!

Popular Cable Tie Molds for Sale

Providing customers with quality service is the ultimate goal of Hing Tung. We are a one-stop cable tie mold manufacturing company, providing hundreds of solutions to your queries. Through the unremitting efforts of our engineers, you will get excellent quality plastic cable tie molds in Hing Tung.

Nylon Cable Tie Mould

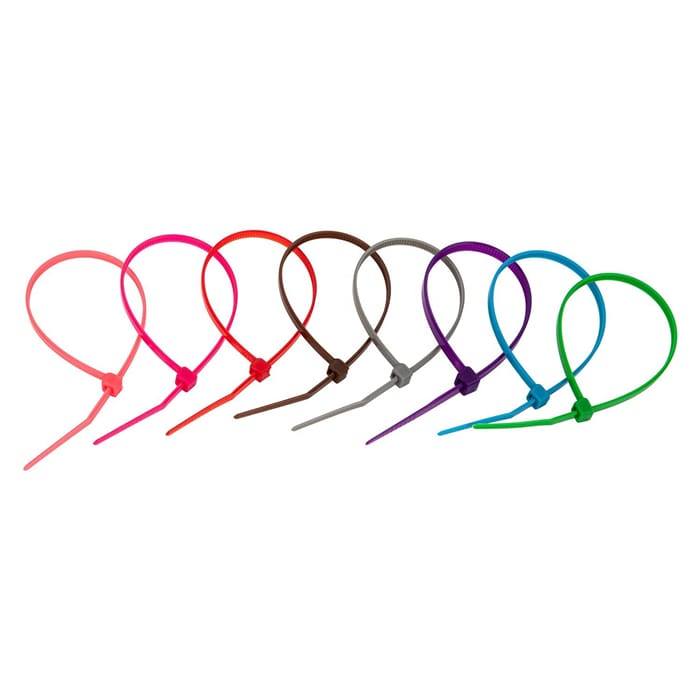

Nylon cable ties, or zip ties, have versatile applications across industries, including electronics, automotive, and construction. They excel at bundling and organizing wires, cables, and hoses, ensuring neatness and safety. Benefits include ease of use, cost-efficiency, and durability, with resistance to moisture and chemicals making them suitable for various environments.

Industrial Cable Tie Mould

Industrial ties are essential for fastening and organizing in manufacturing and construction. They securely hold components, manage cables, and even support plants in agriculture. The benefits encompass cost-effectiveness, simplicity, durability in harsh conditions, and adaptability to different needs, reducing labor costs and ensuring safety.

Double Loop Cable Tie Mould

Double loop cable tie molds enable the production of cable ties with two loops, offering versatility in securing items with varying sizes. They find applications in the automotive industry for wiring harnesses and in agriculture for plant support. Benefits include customizable lengths, enhanced flexibility for irregular shapes, and efficient, specialized production, increasing utility in diverse sectors.

Our Customization Services for Cable Tie Moulds

Package Delivery

Hing Tung uses premium packaging to protect your Cable Tie Mould products until they are delivered safely to your doorstep.

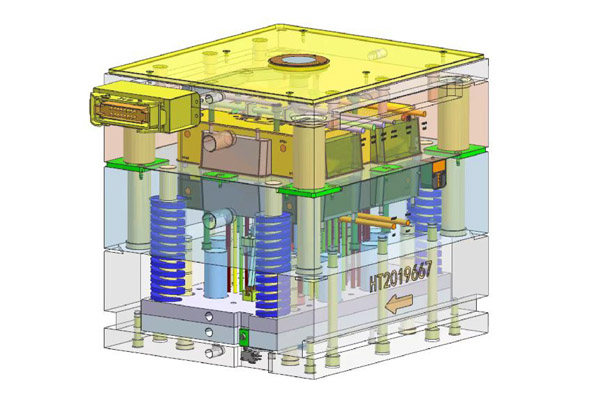

Cable Tie Mould Details

| Place of Origin | China |

|---|---|

| Brand Name | Hing Tung |

| Model Number | customized |

| Product Material | P20/718/738/NAK80/S136 |

| Shaping Mode: | Plastic Injection Mould |

| Cavity: | Single or multi Cavity |

| Mold Life: | 1000000-1500000shots |

| Mould Runner: Cold Runner, Hot Runner | Cold Runner |

| Material: | steel |

| Lead Time: | 4~7 Weeks |

| Packaging Details: | By wooden pallet / by wooden case / could pack as to client’s requirements. |

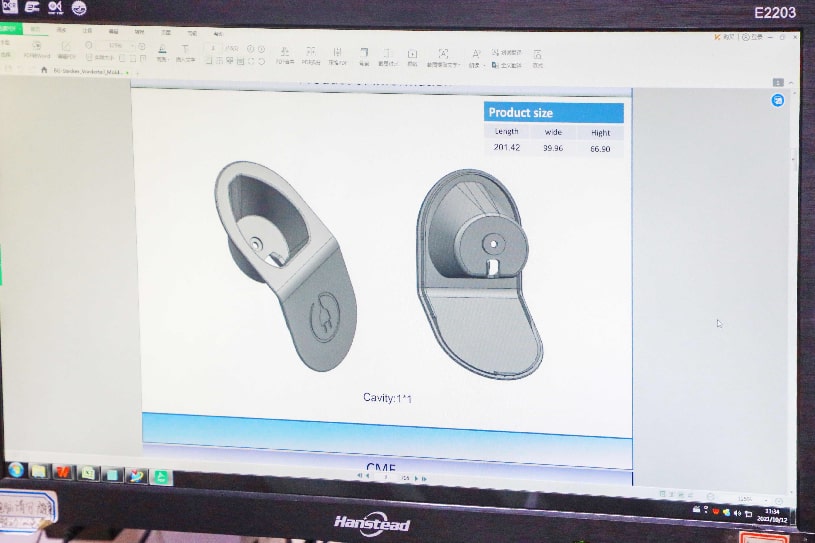

Custom Cable Tie Moulds Designed by Experts

Cable tie mold design is a basic but important part of injection molding, regardless of the size and location of the gate, the size of the shear edge, flow assistance, cooling and ejection technology, will affect the final cable tie mold injection results. It is no exaggeration to say that cable tie mold design has a significant impact on the cost-effectiveness and quality of cable tie products.

The concerted efforts of our various departments provide a strong guarantee for Hing Tung to provide high-quality cable tie molds in a short period of time.

We provide a one-stop custom service to handle your project from concept to mass production, get a free quote now!

Plastic Cable Tie Molds: 2023 FAQ Guide

If you plan to customize or source cable tie moulds, then you may encounter various problems. To better understand cable tie moulds, please read the following FAQ guide, designed to answer your questions.

1: Can Hing Tung provide custom cable tie molds for sale?

Yes, we can customize cable tie molds according to your specific requirements. Please provide us with as much information as possible, including the size of the tie you need, the type of plastic you want to use, and any other specifications you may have. We'll work with you to create a mold that meets your needs. The process usually takes about two weeks but may vary depending on the complexity of the request.

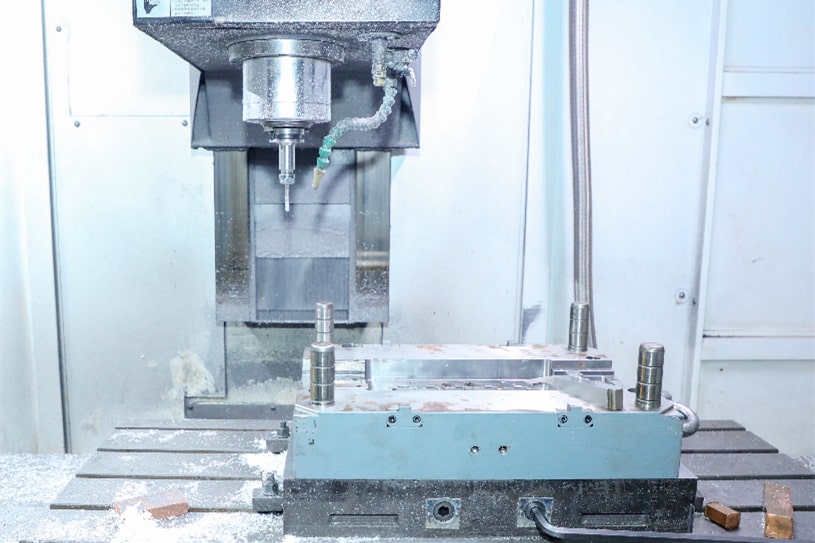

2: How to inspect the quality of cable tie mould?

We inspect all molds before shipping them to customers. We use a range of inspection tools and techniques to ensure each mold meets our high-quality standards. We also carry out a strict testing process after mold production. This ensures that the finished product meets your needs.

3: Besides cable tie molds, what types of molds do you have?

Currently, we provide many types of injection molds, such as Cable Tie Moulds, automobile molds, turnover box injection molds, etc. If you have a specific request for a mold type that is not currently available on our site, please let us know and we'll see if we can create it for you. Our team of experts has extensive experience in creating custom molds, so you can rest assured that we will be able to meet your requirements.

4: Can I visit the Hing Tung factory before placing the mold order?

Yes, you are welcome to visit our factory before placing an order. We'd be happy to show you around and answer any questions. Please let us know when you would like to come and we will arrange it for you. We may also offer facility tours on our website. We recommend that you notify us at least two weeks in advance of your planned visit.

5: Can you help me choose single-cavity and multi-cavity cable tie mould?

Yes, we can help you choose between single and multi-cavity molds. Single-cavity molds are used for smaller products, while multi-cavity molds are used for larger products. Our professional sales staff will be happy to help you choose a mold that suits your needs. Send us an email and our team will get back to you as soon as possible.

6: I don't have a 3D drawing file; how do you make a custom cable tie mold for me?

If you don't have a 3D drawing file, we can create one for you. We have a team of experienced engineers who can create accurate 3D drawings according to your specifications. After the 3D drawing is approved, we will start to make the mold. If you have any questions or need assistance with your 3D drawing files, please feel free to contact us.

7: As a customer of Hing Tung, is there any way to manage the progress of the whole project?

Yes, we have a project management system that allows you to track the progress of your project. This is divided into three phases:

In the first stage, you will provide your requirements and provide a quote.

In the second stage, we will send you the prototype for approval.

In the third stage we will make the necessary changes and send you the final product.

Thereafter, your order will be placed in our production queue and manufactured and delivered to you as quickly as possible.

8: Why am I working with Hing Tung?

Hing Tung is a trustworthy and reliable partner with many years of mold making experience. We always put our customers first, ensuring you get the highest quality product possible. There are many companies offering mold making in China, but few can provide the level of quality and service that Hing Tung offers. So, if you are looking for a trustworthy quality mold manufacturing company, Hing Tung is the right choice for you.

9: How can I place an order?

You can place an order by contacting us directly at the phone number we provide or by filling out our online quotation form. Then we will send you a quotation and if you are satisfied with it, we will move on to the next stage.