Pipe Fitting Mould

Your Trustworthy Partner That Offers Impeccable Plastic Pipe Fitting Mould Services.

China Pipe Fitting Mould Brand

Find the best plastic Pipe Fitting moulds with us

Hing Tung is a company specializing in the design and manufacture of plastic pipe molds and other plastic molds, located in Shenzhen, China. We are the leading manufacturer and exporter of plastic parts molds in China.

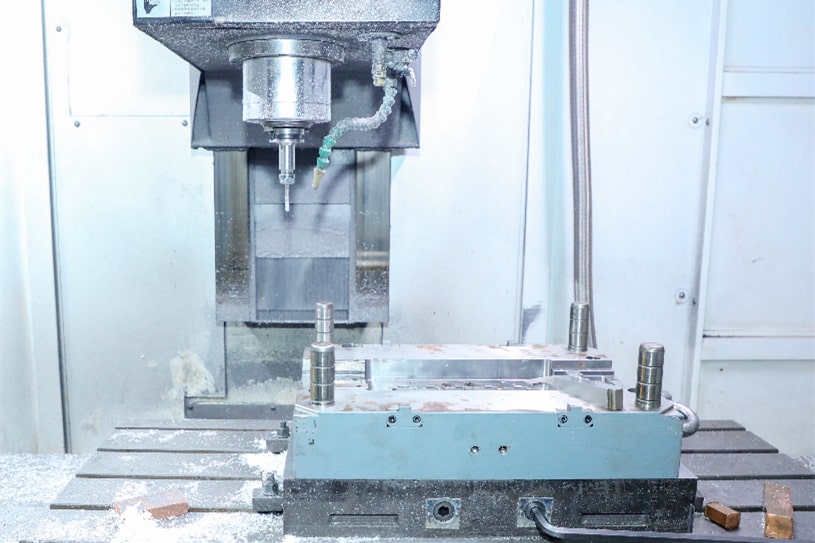

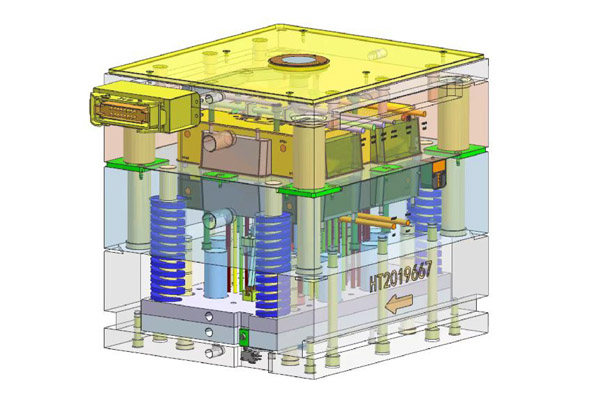

Our factory has rich expertise in mold development and research, and has advanced CNC machining centers, CNC EDM, wire cutting and other advanced processing equipment. At the same time, we introduce internationally advanced 3D design software and skillfully use CAD, UG, PRO/E and other software for product analysis, design, mold design and manufacturing. Targeting users and local manufacturing advantages, the shortest delivery times, highest production efficiency and most consistency are guaranteed.

Choose the Pipe Fitting Mould Design You Need

As a professional pipe fitting mold manufacturer and supplier, Hing Tung Mold provides PVC, UPVC, PPH, PPR and other pipe fitting molding solutions. We specialize in manufacturing any type of pipe fitting mold you need. We have extensive experience in many types of plastic pipe fitting molds, including plastic elbows, T-joints, tees, etc. Hing Tung Mold provides good suggestions according to customers' requirements and designs molds with different structures according to the customer's injection molding machine size.

Custom Hoodie

A hoodie is a type of sweatshirt, jumper, or jacket that features a hood. The style is typically worn for casual wear or sportswear, for which people often partner it with sweat pants. The garment is a protective piece of outerwear that is both comfortable and warm with a fitted waistband and cuffs to trap heat.

Custom Jacket

A jacket is a garment for the upper body, usually extending below the hips. A jacket typically has sleeves and fastens in the front or slightly on the side. A jacket is generally lighter, tighter-fitting, and less insulating than a coat, which is outerwear. Some jackets are fashionable, while others serve as protective clothing. Jackets without sleeves are vests.

Custom T-shirts

A T-shirt, or tee shirt, is a style of fabric shirt named after the T shape of its body and sleeves. Traditionally, it has short sleeves and a round neckline, known as a crew neck, which lacks a collar. T-shirts are generally made of a stretchy, light, and inexpensive fabric and are easy to clean.

Custom Tracksuits

A tracksuit is an article of clothing consisting of two parts: trousers and a jacket usually with a front zipper. It was originally intended for use in sports, mainly for athletes to wear over competition clothing (such as a running shirts and shorts or a swimsuit) and to take off before competition. In modern times, it has become commonly worn in other contexts.

Custom Sweatshirts

A sweatshirt is a typically loose, warm shirt, most often found with long sleeves; A sweatshirt is also much more utilitarian and versatile than a sweater or a jacket, mainly because a sweatshirt can accommodate many kinds of detailing, from collars to front buttons, to cropped cut and can be styled in many different ways.

Our Customization Services for Plastic Pipe Fitting Mould

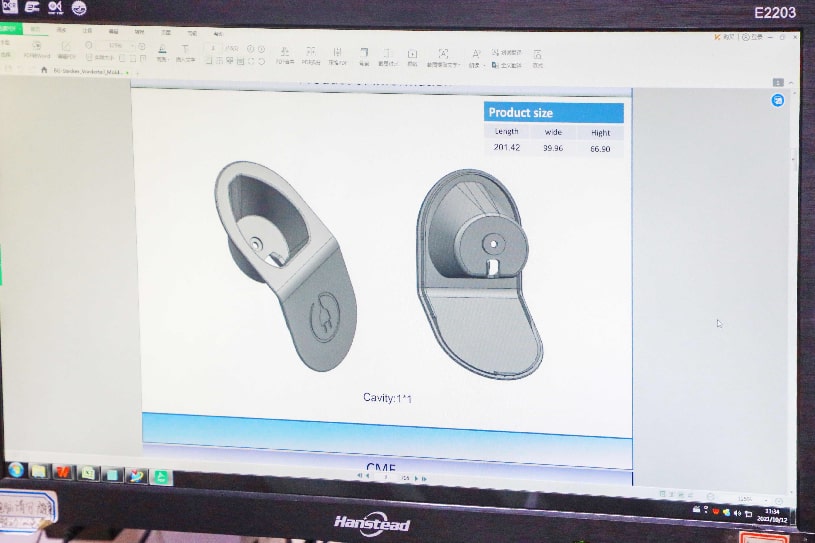

Plastic Pipe Fitting Mould Design

Hing Tung mold design team has rich experience in developing molds for different plastic Pipe Fittings.

Package Delivery

Hing Tung uses premium packaging to protect your Plastic Pipe Fitting Mould products until they are delivered safely to your doorstep.

Plastic Pipe Fitting Mould Details

| Place of Origin | Shenzhen, China |

|---|---|

| Brand Name | Hing Tung Mould |

| Product Material | Plastic |

| Product | Plastic Pipe Fitting Mould |

| cavity | multi cavity |

| design | 3D or 2D |

| runner type | cold runner |

| Mould Steel | P20H/718/2316/2738etc. |

| mould base | LKM,HASCO,DME |

| mould life | 500,000~1million shots |

| sample time | 50 days |

Custom Plastic Pipe Fitting Moulds Designed by Experts

Hing Tung is China's leading PVC pipe fitting mold, pipe fitting mould, PVC ball valve mold and PVC pipe fitting mold manufacturer, PVC plastic pipe fitting mold, PVC pipe fitting injection molding manufacturer. Hing Tung's services include prototyping, mold manufacturing, laboratory testing, sampling, commissioning, mass production and assembly.

Hing Tung provides China PVC pipe fitting mold manufacturers with about 10 years of experience. Since we regard customer satisfaction as our highest goal, we strive to provide them with high-quality products and competitive prices.

Plastic Pipe Fitting Moulds: 2023 Guide

Plastic pipe fittings have become very popular these days for water supply and drain lines. The low cost, good durability, and easy installation have made plastic pipes most popular.

If you plan to customize or source plastic Pipe Fitting molds, then you may encounter various problems. To better understand plastic Pipe Fitting molds, please read the following FAQ guide, designed to answer your questions.

What is a Pipe Fitting Mould?

Pipe fitting molds are usually used to produce plastic pipe fittings of various shapes. Pipe fitting molds are divided into three categories: extrusion, die casting, and forging. Extrusion dies made from metals, plastics, and composites are often used to make smaller pipe fittings such as elbows, tees, and reducers. Die-cast molds made of metal produce larger pipe fittings such as flanges and joints. Forging dies are also made of metal and create the most common types of pipe fittings.

Likewise, pipe fitting molds are a means of producing high-quality, finely constructed plastic molded pipe fittings. Plastic injection molded pipe fittings are a great, low-cost alternative to metal pipe fittings in many ways. Experts at the Hing Tung manufacturing site create reliable pipe-fitting molds. We can also make molds according to your needs. You can contact our customer service representatives to resolve your queries and place your order.

What Materials Are Suitable for Pipe Fitting Molds to Produce Products?

Pipe Fitting Mould is a system designed to create custom plastic Pipe Fittings. The mould allows for the creation of hundreds and thousands of uniform, durable and safe customized products. Plastic mold has many advantages over traditional wooden mold: it’s made from high-quality materials that can handle heavy loads; they’re easy to clean and maintain as well as being strong enough to carry large weights without breaking or cracking like traditional wooden Pipe Fittings.

In addition, these systems are also designed with safety in mind making them great for use in industrial environments where there may be risks involved such as gas leaks or spills, etc.

How much does it cost to buy a Pipe Fitting Mould?

Usually the price of a plastic tray mold is around $1,000.00 - $25,000.00. The specific price depends on the complexity of the mold design, the size and specification of the tray, the material used in the mold, the manufacturing process and the location of the mold supplier.

How long can the plastic tray mold be used?

Plastic injection molds last from hundreds to over a million cycles. The life of an injection mold depends on its environment, maintenance, structure, type of plastic material used, molding process conditions, and other factors.

What Pipe Fitting Moulds can you provide?

We can provide to customers: Block Pipe Fitting Molds, Stringer Pipe Fitting Molds, Nestable Pipe Fitting Molds, Rackable Pipe Fitting Molds, Hygienic Pipe Fitting Molds, Export Pipe Fitting Molds. Of course, we can also customize the tray mold for you according to your needs.

How to ensure the quality of delivered Pipe Fitting molds?

After the Pipe Fitting mold design is ready, the mold design quality control department will start to check the mold design. * Mold structure inspection * Mold action and guide system inspection * Mold injection system inspection * Mold cooling system inspection * Mold ejection system inspection * Mold vulnerable area inspection, etc.

Make sure the mold you receive is normal without any quality problem!

Can you design the tray mold for me?

If you don't have a 3D drawing file, we can create one for you. We have a team of experienced engineers who can create accurate 3D drawings according to your specifications. After the 3D drawing is approved, we will start to make the mold. If you have any questions or need assistance with your 3D drawing files, please feel free to contact us.

Why choose Hing Tung's tray mold?

Hing Tung is a trustworthy and reliable partner with many years of experience in mold making. We always put our customers first, ensuring you get the highest quality product possible. There are many companies offering mold making in China, but few can provide the level of quality and service that Hing Tung offers. So, if you are looking for a trustworthy quality mold manufacturing company, Hing Tung is the right choice for you.

How can I order tray molds?

Step 1: Please let us know the size of the plastic tray you would like to make. Or send us your cable tie samples by express. A detailed price list will be provided as soon as possible.

Step 2: After the order is confirmed, the mold drawing will be given.

Step 3: Start production after the mold drawing is confirmed

Step 4: Update the mold production schedule

Step 5: Make a trial run on the new Pipe Fitting mold and send the new sample to the customer.

Step 6: The customer confirms the sample.

Step 7: Packaging and Shipping