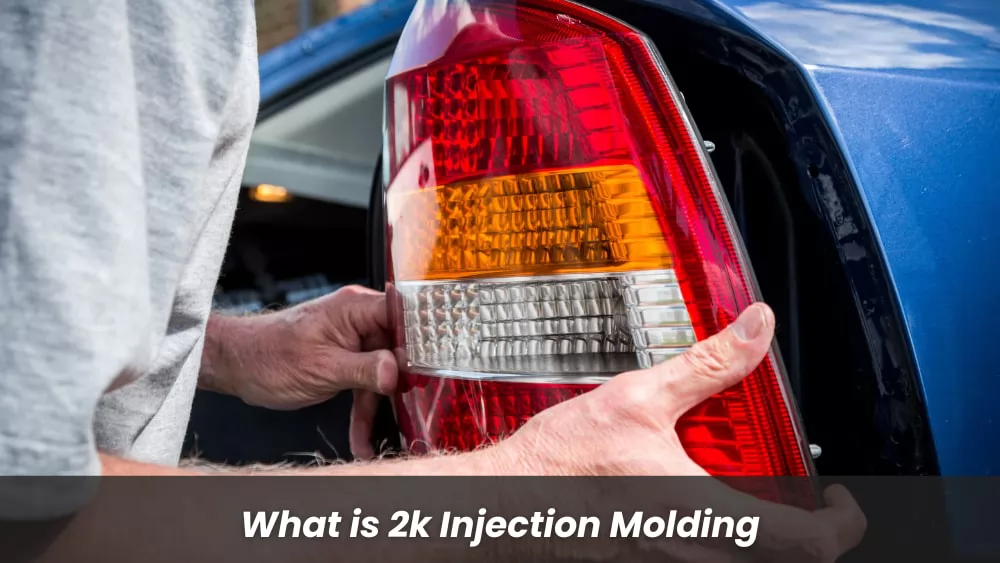

2K moluding is well known as 2 shot injection molding or two color injection molding, the final product is made from two different plastics or two different colors of one plastic through one injection molding process. It applies to a wide range of products; think medical equipment, the keys on a computer keyboard, or even all the specific parts in a car's headlights.

In this guide, we'll explore how 2k prototyping works, its main applications, and its pros and cons.

What is 2k Injection Molding?

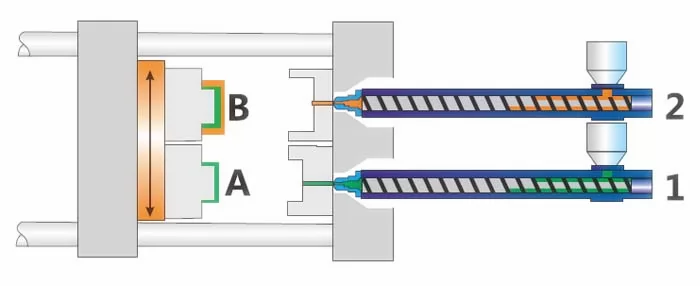

2K injection molding is a production process in which two materials (colors) are processed in one plastic part. This plastic molding technology combines two materials or two different color materials into one ending plastic part using a 2K injection molding machine.

The chemical bonding process involved in this happens because they are capable of joining two or more materials into one part. When using a 2K injection molding technology process, the choice of material will be the most important factor for the project’s success. Two completely opposite polymers can be used for a ready-to-use product.

Advantages of 2k injection molding

With 2K injection molding, we can inject a plastic into the mild with one or more separate injections. This gives a very precise split line between the different materials, such as the difference in hardness of material or a difference in colour etc.

Appearance

The 2K injection moulding technique can be more attractive from an aesthetic point of view because the 2 components fit together seamlessly as product can be made in 2 colours (2K) in one production process.

Save costs

Because the 2K technology assembles assembly steps together into one injection moulding process, the cost price of your product is often lower.

User-compliant and tailor made products

The practical use is an important aspect in product development. Hard plastic is not always user-friendly. It is then possible to finish the product with softer edges or a complete soft plastic cover, which increases user comfort. When producing a soft seal in the second shot, products can be made fit for use in watertight applications etc.

Disadvantages of 2k injection molding

The one-time investment costs of 2k injection moulding are a bit more expensive when compared with a single stage injection moulding process. However, these costs are in most cases quickly recovered because assembly steps and hand labour can be eliminated.

Not all plastic combinations are possible because some plastics do not adhere sufficiently to each other.

Different Applications for 2k Injection Molding

2K injection moulding is perfect for combinations of hard and soft plastics and also if you want to process 2 colours of plastic in one product.

Examples of 2K injection moulding are products made from a hard plastic with a 2nd soft plastic edge that serves as a seal (for instance a lid-seal ). With the 2K injection moulding technique we produce complete products in 2 steps. Well-known examples are bicycle handlebar grips, toothbrushes with a hard handle and a soft handle piece , control buttons, anti-slip applications etc.

What’s the Difference Between 2k Moulding and Overmoulding?

A common question. Let’s first define overmoulding.

Overmoulding is also a type of injection moulding process that allows for the combination of two or more different materials into a single product. This usually includes a rigid, plastic-base component overlaid with a pliable, thin rubber-like thermoplastic elastomer (TPE) exterior layer or other materials using either a 1 shot (insert moulding) or 2 shot (2k) technique.

The main differences between overmoulding and 2k moulding can be summarised as follows:

- Overmoulding can be both a single shot (insert moulding) or two-shot. 2k moulding is just a 2 shot process.

- Production volume. 2k tends to be a lot bigger than overmoulding and is used for larger operations.

- In the overmoulding process, the material used must be cold to be removed. However with 2k moulding, the polymer is typically still flexible and hot – therefore it allows for more greater functionality.

- 2k moulding allows for large number of materials that can act as the moulding substance or equally be moulded on. With overmoulding, you are more restricted with the usable materials.

Frequently Asked Questions for 2k Molding

What are the benefits of using the 2k injection molding process to manufacture products?

High precision, stable quality, good structural strength and durability, small gaps, beautiful appearance, lower production costs, and increase the value of composite products.

What are the benefits of 2k molding for medical devices?

The most obvious advantage is that it can create the most complex and innovative products. As mentioned, you are basically free to use the best material for a given product. Since the most complex parts require different materials for different functions.

What materials are suitable for 2k molding?

There are mainly nylon, thermoplastics, metals, thermosetting plastics, rubber, glass, etc.

Hingtung: Market Leader in 2k Injection Molding

As a strong 2K injection molding partner, Hingtung will be happy to advise you. When selecting the appropriate material and determining the best processing method. In this way, we ensure that the final product exactly meets or exceeds your expectations.

We will be happy to calculate for you whether 2k injection molding is the right solution for you, or if another injection molding option is a better fit for your product.

For more information on Overmolding, Contact Us Now.