Injection molding technology has always been a treasure in the industry. The technology works by injecting molten plastic into molds, which then cools and solidifies, creating a variety of uniquely shaped and versatile products. However, there are many challenges and choices we must face when choosing a product suitable for injection molding. Which products are the best choices? How do they meet our needs and bring us more surprises? Let's embark on a journey to find the perfect way together.

Article Directory:

1.What are the applications of injection molding products?

2.What are the common injection molding products in life?

2.3Injection molding products in the cosmetic packaging industry

2.4Typical products of injection molding

2.6Agriculture

2.7Household

What are the applications of injection molding products?

There are many kinds of injection molded products, and the scope of application is relatively wide, especially in the textile equipment and automobile manufacturing and processing industries, the shapes of injection molded products for accessories are various. Medical equipment, stationery, educational supplies, and various containers, and boxes can be seen everywhere in people's daily life.

Injection molding products are widely used in transportation, packaging, post and telecommunications, communications, construction, home appliances, computers, aerospace, national defense and other fields of the national economy, and have become indispensable means of production and consumer goods.

What are the common injection molding products in life?

1. Medical industry

At present, there are many types of injection molding products in the medical industry, and the medical care industry is highly dependent, such as highly transparent PPT droppers, electronic thermometer shells, injection molded parts for spray machine shells, medical hands for laser writing instruments, plastic shells for physiotherapy thermal spine and neck instruments, medical sharps boxes, There are dozens of varieties of housings for medical virus detectors and oral X-ray machines.

2. Home appliance industry

Our common ones are hand-held fans, humidifier shells, heater shells, rechargeable hand warmers, blenders, rice cooker shells, air conditioner shells, TV shells, hair dryer shells, water heater shells, etc.

3. Injection molding products in the cosmetic packaging industry

In the past, many cosmetic packaging materials were made of glass materials. The main disadvantage is that the materials are too heavy, easy to break, and the price is relatively expensive. Now plastic materials are gradually replacing glass materials. Plastic materials account for 90% of cosmetic packaging materials. Common products include lipstick tubes, powder cases, lip gloss tubes, eyebrow pencils, lip gloss tubes, refill bottles, cosmetic bottles, etc. Dozens of varieties.

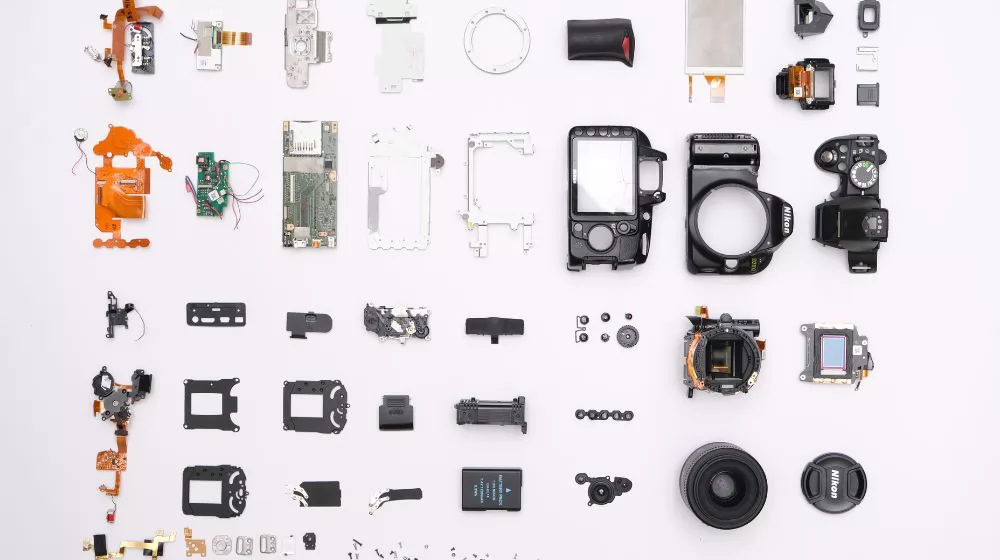

4. Typical products of injection molding

Plastic bottles are the most common product, with billions of them produced every year in all shapes and sizes. Typically, plastic bottles used to hold drinking water and other beverages are made of polyethylene terephthalate (PET) because the material is both strong and lightweight.

5. Electronic housing

They are also very commonly manufactured by injection moulding. Custom plastic housings for devices such as remote controls, computers, televisions, medical devices, and other consumer electronic components are produced through the injection molding manufacturing process. Injection Molding Process Services can fabricate virtually any custom plastic enclosure for any application and size.

6. Agriculture

We can see the important role of injection molding in agricultural irrigation systems. For example, accessories such as sprinkler nozzles, drip irrigators, sprinklers, etc. are manufactured by injection molding. Injection molding technology can produce high-precision irrigation equipment to ensure that water is evenly delivered to farmland and improve crop growth. At the same time, the corrosion resistance and durability of injection molding materials also enable these irrigation accessories to be used for a long time under harsh environmental conditions, bringing farmers more stable yields and economic benefits.

7. Household

Household appliances are also a common application area for injection molding technology. From television casings to washing machine panels, injection molding gives home appliances their distinctive designs and fine details. The plasticity and durability of injection molding materials allow home appliances to withstand the test of daily use and provide us with long-lasting service. In addition, injection molding can also realize the lightweight design of home appliances, improve energy efficiency, and create a more environmentally friendly and intelligent home living environment for us.

8. Machinery and auto parts

Bumpers, dashboards, radio controls, cup holders and many other elements in cars and vehicles, both interior and exterior, are manufactured through the injection molding process.

What are the other advantages of injection molding?

Injection molding can also provide some additional properties to the product. For example, by adding special additives, the flame retardancy, UV resistance and antistatic ability of the plastic can be increased, making the product safer and more durable. In addition, multi-color injection molding can also be realized during the injection molding process, so that the product has a richer appearance effect. These additional features add unique value and appeal to the product.

Summarize

In our quest for perfection, injection molding technology offers us a wide range of possibilities. It can not only manufacture products of various shapes, but also meet the needs of different industries. Whether pursuing innovation, mass production or optimizing product characteristics, injection molding can help us achieve our goals.

If you want to use this kind of process to make products, you can contact HingTung to help you realize it.

HingTung has more than 25 engineers, from project management, mold design to mold manufacturing, we are committed to shortening the R&D cycle for customers, improving product quality, and providing efficient and high-quality services. We have five-axis CNC, GF high-speed CNC, GF high-precision spark machine and electric high-speed precision injection molding machine. The injection molding workshop adopts the MES system, and the company's operation and customer relationship management adopt the ERP and CRM systems, which are integrated with the financial system into a unified platform management system. Give you the best one-stop solution for structural parts.