Are you looking for a reliable mold manufacturer to customize automotive molds for your project? Then congratulations, you have found the right place. Hingtung is the largest plastic molding and mold manufacturing company in China.

We specialize in designing and customizing various types of auto parts molds and plastic products. If you need us to serve you, the following information will help you.

The global automotive plastics market was valued at USD 21.1 billion in 2021 and is projected to reach USD 30.8 billion by 2026, growing at a cagr of 7.9% from 2021 to 2026. If you want to start a business with custom auto parts molds, then this article will help you.

You can learn from this article:

- What Is an Auto Parts Mold?

- Why Choose Injection Molds for Automotive Plastic Parts?

- What Parts Can Be Produced by Auto Parts Molds?

- How Much Does It Cost to Customize a Car Part Mold?

- What Materials Are Used to Make Auto Parts Molds?

- How to Check the Quality of Auto Parts Molds?

- How to Choose High-Quality Automotive Injection Molds?

- What Materials Does the Automotive Mold Support for Molding?

- What Are the Well-Known Automotive Mold Suppliers?

- Custom Car Parts Mold FAQ

- Your Trustworthy Automotive Injection Mold Company

Chapter 1: What Is an Auto Parts Mold?

An auto parts mold, also called an auto parts plastic injection mold, is a precision-machined mold designed to shape materials such as plastic or rubber into specific automotive plastic parts. These injection molds are critical in producing a variety of vehicle components, from interior trim such as dashboards and panels to exterior parts such as bumpers and lights.

Chapter 2: Why Choose Injection Molds for Automotive Plastic Parts?

Choosing injection molds for automotive plastic parts offers several advantages that make it a preferred manufacturing method in the automotive industry:

● Precision and Consistency: Injection molding provides high precision and consistency in the production of automotive plastic parts. The process ensures uniformity in each part, meeting strict quality standards.

● Complex Geometries: Injection molds can handle the production of intricate and complex geometries in automotive components. This capability is essential for manufacturing parts with detailed designs and specific functional requirements.

● Cost-Effective for Large Volumes: The tooling costs associated with injection molds can be distributed across a large production volume, making it cost-effective for the mass production of automotive plastic parts.

● Material Versatility: Injection molding supports a wide range of materials, offering flexibility in material selection for different automotive applications. This includes various types of plastics with different properties.

Chapter 3: What Parts Can Be Produced by Auto Parts Molds?

| Category | Examples of Plastic Parts |

|---|---|

| Interior Components | Dashboard components, door panels, center console parts, seat components, trim |

| Exterior Components | Bumpers, grille inserts, exterior trim pieces, side mirror housings |

| Lighting Systems | Headlamp and taillight housings, turn signal components, fog light enclosures |

| Under-the-Hood Parts | Engine covers and shrouds, air intake components, radiator tanks and fans |

| Functional Parts | Connectors and housings for electrical components, brackets, mounts, clips |

| Interior Trim | Cup holders, storage compartments, interior trim panels, HVAC system components |

| Electronic Components | Sensor housings, control unit casings, wiring harness components |

| Miscellaneous Parts | Wheel covers, license plate frames, interior and exterior decorative elements |

Chapter 4: How Much Does It Cost to Customize a Car Part Mold?

The cost of custom auto part molds typically falls within a wide price range, as a general guideline:

Low-End Range: For simpler designs, smaller molds, and lower quantities, the cost may start at a few thousand dollars.

Mid-Range: Moderate complexity, average-sized molds, and moderate production volumes could range from $5,000 to $20,000.

High-End Range: Complex designs, larger molds, high-precision requirements, and larger production volumes may lead to costs exceeding $20,000 and can go well into the six-figure range.

It's crucial to note that these figures are approximate and can vary based on specific project requirements, materials used, and the expertise of the mold manufacturer.

Customization costs are often influenced by the unique aspects of each project, so obtaining detailed quotes from experienced mold designers and manufacturers is essential for accurate pricing.

Chapter 5: What Materials Are Used to Make Auto Parts Molds?

Auto parts molds are typically made from durable and high-quality materials to withstand the demands of the injection molding process and ensure the production of precise and consistent automotive components. Common materials used for making auto parts molds include:

1. Tool Steel:

P20 Steel: A versatile, low-alloy tool steel suitable for medium to large-sized molds.

H13 Steel: Known for its high hardness and resistance to thermal fatigue, making it suitable for high-temperature applications.

2. Stainless Steel:

Stainless Steel 420: Offers good corrosion resistance and high hardness, suitable for molds with moderate production volumes.

Stainless Steel 316: Provides excellent corrosion resistance and is often used for molds requiring resistance to corrosive environments.

3. Aluminum:

7075 Aluminum: High-strength aluminum alloy suitable for prototype or low-volume production molds due to its lower wear resistance compared to steel.

4. Beryllium Copper:

C17200 Beryllium Copper: Known for its high thermal conductivity and durability, often used for specific applications requiring rapid heat dissipation.

Chapter 6: How to Check the Quality of Auto Parts Molds?

Checking the quality of auto parts molds is a critical step in ensuring the production of precise and consistent automotive components.

1. Dimensional Accuracy

Verify that the molded parts meet the specified dimensional tolerances and match the design specifications.

2. Surface Finish

Inspect the surface finish of the molded parts for smoothness and uniformity. A high-quality mold should produce parts with an appropriate surface texture.

3. Material Compatibility

Ensure that the mold material is compatible with the type of material being molded. Different plastics may require specific mold materials to prevent wear and corrosion.

4. Tooling Wear and Tear

Examine the mold for signs of wear, such as erosion, pitting, or scratches. Wear on the mold can impact the quality of the molded parts.

5. Injection System Performance

Check the performance of the injection system, including the nozzle, runner system, and gating. Ensure proper filling of the mold cavity without causing defects.

6. Cooling System Efficiency

Evaluate the effectiveness of the cooling system to prevent uneven cooling and warping of the molded parts. Proper cooling is crucial for maintaining dimensional stability.

7. Quality of Ejector System

Inspect the ejector system for proper functioning. Ensure that the molded parts are ejected smoothly without causing damage.

Chapter 7: How to Choose High-Quality Automotive Injection Molds?

Certainly! Choosing the right automotive injection mold is a crucial decision that can impact the quality, efficiency, and cost-effectiveness of your production. Here are some key pieces of advice to guide you in selecting an automotive injection mold:

1. Define Your Requirements

Clearly outline your project requirements, including the type of automotive parts you need, production volume, material specifications, and any specific design considerations.

2. Research Reputable Mold Manufacturers

Look for established and reputable mold manufacturers with a proven track record in producing high-quality molds for the automotive industry. Research their experience, client reviews, and industry reputation.

3. Evaluate Material Options

Consider the material options for the mold. The choice of material (e.g., tool steel, stainless steel, or aluminum) should align with your production needs, such as volume, type of material to be molded, and expected durability.

4. Examine Previous Work and Samples

Request samples of automotive parts produced using the manufacturer's molds. This allows you to assess the quality of their work and the suitability of their molds for your specific requirements.

5. Check Precision and Tolerance

Inquire about the manufacturer's capabilities in achieving high precision and tight tolerances. This is crucial for meeting quality standards in automotive part production.

6. Understand Costs and Lead Times

Obtain detailed quotes that include all costs associated with the mold, including design, materials, and manufacturing. Additionally, understand the lead times for design, production, and delivery.

Chapter 8: What Materials Does the Automotive Mold Support for Molding?

| Material Type | Common Applications in Automotive |

|---|---|

| Thermoplastics | |

| Polypropylene (PP) | Interior components like dashboards, door panels, and seat components. |

| Polyethylene (PE) | Automotive tubing, containers. |

| Polyvinyl Chloride (PVC) | Cable insulation, upholstery, trim components. |

| Polyethylene Terephthalate (PET) | Engine components, electrical connectors. |

| Thermosetting Plastics | |

| Polyurethane (PU) | Seating, interior trim components. |

| Epoxy Resins | Specialized components with high strength and temperature resistance. |

| Engineering Plastics | |

| Acrylonitrile Butadiene Styrene (ABS) | Interior and exterior components, combining strength and impact resistance. |

| Polycarbonate (PC) | Headlamp lenses, known for optical clarity, strength, and impact resistance. |

| Nylon (Polyamide) | Engine components, structural elements, due to strength, heat resistance, and wear resistance. |

Chapter 9: What Are the Well-Known Automotive Mold Suppliers?

Keep in mind that the landscape of suppliers may change over time, and it's essential to conduct recent research to get the latest information. Here are some reputed automotive mold suppliers:

Hing Tung: A global supplier offering a range of injection molding mold and services for various industries, including automotive.

Mold-Masters: Known for hot runner systems and mold temperature controllers, Mold-Masters is a leading supplier to the automotive and packaging industries.

DME Company: Provides a wide range of mold components and services, serving industries such as automotive, medical, and packaging.

HASCO: A German-based company that supplies standard mold components and accessories to industries worldwide, including automotive.

Futaba Corporation: A Japanese company specializing in the manufacturing of automotive molds, particularly for interior and exterior components.

Moldex3D: While not a mold supplier per se, Moldex3D offers simulation software widely used by mold designers and manufacturers in the automotive industry.

StackTeck: Known for its expertise in stack mold systems, StackTeck provides solutions for multi-cavity, high-volume molding applications, including automotive parts.

OSCO Incorporated: A supplier of die-cutting products, gaskets, and precision molded parts for the automotive industry.

Rocand: A Canadian company specializing in the design and manufacturing of plastic injection molds, with a focus on automotive applications.

Ewikon: A German company that provides hot runner systems and solutions for injection molding applications, including automotive components.

Chapter 10: Custom Car Parts Mold FAQ

Q1: How long does it take to receive a custom car parts mold?

A: It takes about 1~2 week for a simple car mold and 3~4 weeks for a complex mold.

Q2: How much does the car parts mold cost?

A: The cost of creating a custom automotive mold depends on many factors, including the complexity of the design, the size of the mold, and the materials used. Prices for custom automotive molds range from a few thousand dollars to tens of thousands of dollars.

Q3: Can the mold be modified according to my requirements?

A: Yes, we can customize a car mold that fits your project according to your requirements.

Q4: Can custom automotive molds be used for mass production?

A: Yes, custom car molds can be used for mass production of cars. Once a mold is created, it can be used to create multiple copies of the same body. This allows for efficient and cost-effective manufacturing of custom cars.

Chapter 11: Your Trustworthy Automotive Injection Mold Company

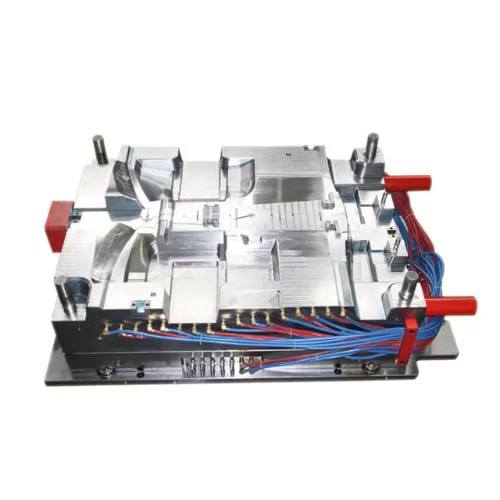

Hingtung Mold is one of the large-scale mold design and mold manufacturers in China, with many years of experience in automotive molds, such as dashboard molds, front bumper molds, radiator grille molds, mirror molds, trim strip molds, rear Bumper molds, headlight mold, pillar mold, center console mold, door panel mold, etc.

Hingtung has perfected the quality management system, such as process management, technology and training, quality control, and mold design for plastic molds. So far, Hingtung has served more than 30 countries and regions at home and abroad. We provide customers with technical support, after-sales service, etc.

Automotive Parts Molds We Have Successfully Delivered

We are able to design and manufacture auto parts molds that meet your requirements. The molds we have successfully delivered include automotive interior and exterior trim molds, lamp molds, Mucell foam molds, low-pressure injection molds, gas-assisted injection molds, etc.

Highlights About Our Automotive Molds

- Our professional service includes engineering, mold making, prototyping, and tooling

- From single prototype to OEM and ODM high professional volume production, We can manage all our client's plastic injection molding requirements.

- Except for making the mold, we also provide injection molding service, compression molding service (especially for silicone rubber material compounding with various colors matching and production jobs for specific product needs), or punch die production service.

- Our injection mold testing machine is available 50~250T in-house, and 300~3000T in the associated party.

- Per each project need, we also design and provide fixture and jig-making services for stabilizing some easily deformed parts need.

- Per customer’s need, we also provide chrome plated, painting, ultra-sonic welding, assembly, or packing/printing service.

- We provide low volume, pilot run of production jobs, and mass production for customers.