Are you planning to buy new plastic bucket molds to start a new business? Hingtung is one of the top plastic bucket mold manufacturers and exporters in China. We specialize in the production of plastic paint bucket moulds, water bucket molds, baby bucket molds, food bucket molds, mop buckets and other types of plastic buckets.

We are committed to providing our customers with the best Plastic Bucket Mold products and services, we strive to always exceed their expectations. During the manufacturing process, Hingtung is able to manufacture complete paint buckets (lids, buckets and handles) in a timely manner and has the ability to provide custom assembly, stamping and packaging services when necessary.

1. What is a Bucket Mould?

Bucket mould (Plastic Bucket Mould) is a specialized tooling used in the plastic injection molding industry for manufacturing plastic buckets of various sizes, shapes, and functionalities. This mould is primarily made from high-quality steel and consists of two main parts: the core and the cavity. The core defines the inside of the bucket, while the cavity shapes the outside.

2. Basic Structure of Plastic Bucket Mould

Key Components and Assembly

Each plastic bucket mould comprises several essential components, including the mould core, mould cavity, nozzle, and cooling channels. These components collaboratively ensure that every injection molding process runs smoothly, producing consistently high-quality and perfectly shaped plastic buckets.

Common Mold Materials

At HingTung, based on our values, we prioritize the quality and durability of our moulds. Therefore, we meticulously choose the materials suitable for our moulds. The primary steel types we utilize include P20, H13, and S136. These materials, renowned for their exceptional wear resistance, corrosion resistance, and stability under high temperature and pressure conditions, are favored in the mold-making industry. These premium mold materials ensure our plastic bucket moulds not only have an extended lifespan but consistently perform throughout the production process.

3. Manufacturing Process of Plastic Bucket Mould

Mold Design

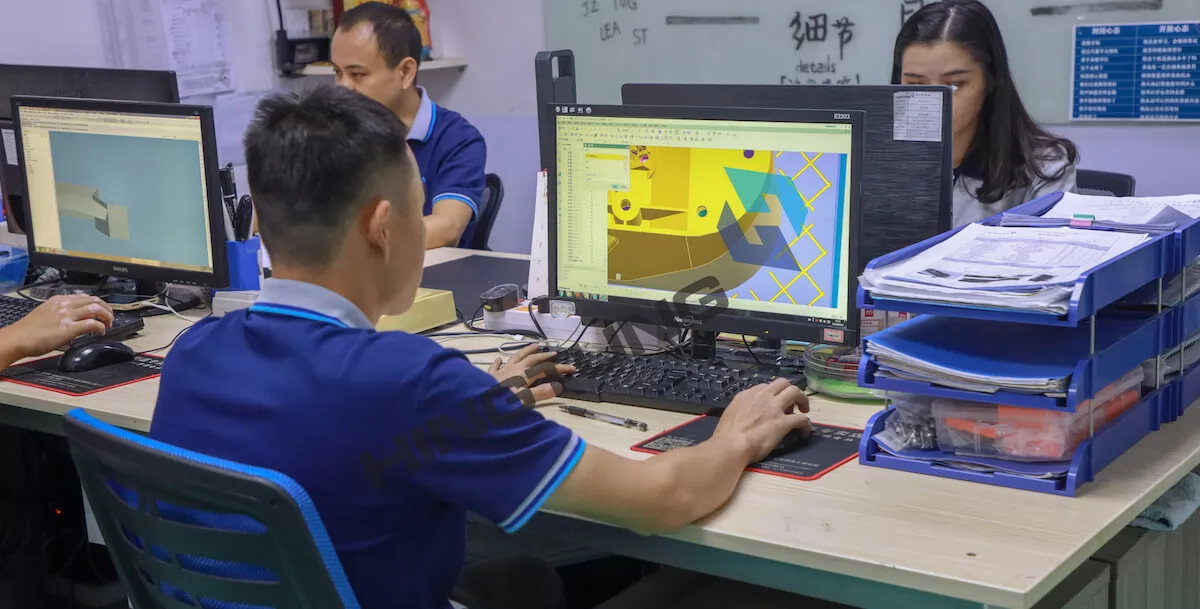

At HingTung, our approach begins with precision. We employ advanced CAD modeling to visualize and refine the mold design of the plastic bucket mould. Every curve, angle, and dimension is carefully examined by our experienced engineers to ensure optimal functionality and aesthetics. Throughout this phase, our team of over 15 engineers collaborates closely, leveraging their collective expertise to forecast potential challenges and devise solutions, ensuring the mold design is both innovative and feasible.

Manufacturing Techniques

Once the design is finalized, the actual mold manufacturing process commences. Equipped with advanced machinery like 5-axis CNC, GF high-speed CNC, and GF spark machines, we can achieve unmatched precision in mold production. Every step, be it CNC machining, electrical discharge machining, or any other process, is executed with an acute attention to detail, ensuring the mold aligns perfectly with the design specifications and upholds the high standards HingTung is renowned for.

Quality Inspection and Fine-tuning

Upon mold completion, it undergoes rigorous quality checks. Our commitment to excellence is manifested by our ISO9000 and ISO14000 certifications. Each mold is scrutinized for accuracy, durability, and efficiency. Should any discrepancies arise, the mold undergoes fine-tuning until it meets our stringent standards. This rigorous approach ensures that when the mold is eventually used for injection molding, the resultant plastic bucket aligns perfectly with our client's expectations and our quality benchmarks.

4. Injection Molding Process for Plastic Buckets

Selection of Injection Molding Machines

Understanding the paramount importance of the right equipment for producing top-tier products, we meticulously select our injection molding machines based on factors like clamping force, shot weight, and tie-bar spacing. If you're considering purchasing injection machines, we can also provide sound advice. We can also assist directly with production.

Choice and Pre-treatment of Plastic Materials

Material selection is pivotal in determining the final product's quality. We recommend sourcing high-grade plastics that ensure durability, flexibility, and a smooth finish. Prior to the injection molding process, these materials should undergo pre-treatment, which could include drying, heating, or mixing with additives, ensuring their optimal molding condition.

Setting Injection Parameters

Crafting the perfect plastic bucket is as much an art as it is a science, requiring the right balance of pressure, temperature, and cycle time. We suggest meticulous setting of these injection parameters post purchasing the plastic bucket mould to guarantee even plastic flow, accurate mold filling, and uniform cooling. This attention to detail ensures each bucket emerges from the mold with consistent shape, thickness, and finish.

Cooling and Final Molding

Once the molten plastic fills the mould, the cooling process initiates. During production, cooling rates and methods should be optimized to avert deformities and confirm the bucket retains its intended shape. After ample cooling, the freshly molded plastic bucket is ejected, inspected for quality, and readied for subsequent stages, be it assembly, packaging, or direct shipping.

5. Maintenance and Care of Plastic Bucket Moulds

Common Issues and Solutions

From our years of observation, even the most intricately engineered moulds can face challenges in the plastic injection molding process. At HingTung, we've documented potential issues like warping, sink marks, or short shots. With our amassed expertise, we've devised robust solutions.

Cleaning and Lubrication

Periodic maintenance of the plastic bucket mould is vital for its extended usability. Residual plastic, dust, or other contaminants can compromise mold efficiency. So, regular cleaning is imperative. Yet, cleaning alone isn't sufficient; lubrication plays a pivotal role too.

Storage and Maintenance Recommendations

Proper storage is as crucial as periodic maintenance. At HingTung, we suggest moulds be stored in a controlled environment, shielded from humidity, extreme temperatures, and other potential damage factors. When a mold is retrieved for production, it should be in prime condition. Furthermore, we advocate maintaining a comprehensive log for each mold, detailing its usage, maintenance history, and any repairs, ensuring traceable history.

6. HingTung Plastic Buckets Design Ability

We are able to design, manufacture and supply your plastic mold requirements regardless of their complexity and or design complexity. Both prototype and bucket mold production are done in-house, so we can meet the individual requirements of each project.

Paint Bucket

Plastic Bucket

Transparent Bucket

7. Top Plastic Injection Molding Bucket and Mold Manufacturer - HingTung

Hingtung can provide professional plastic bucket molds to help you produce plastic buckets efficiently and profitably. Today, markets demand efficiency. Stable quality and long-term efficient production are also required by more and more plastic bucket manufacturers. That's why Hingtung Mold is committed to providing precision solutions for plastic bucket moulds, and finally becomes a reliable partner to support customers in the plastic bucket development and manufacturing process.

8. How We Can Help You Start Your Barrel Mold Business?

1. Plastic Bucket Mold Design

Hingtung has highly advanced molding technology. We utilize the best molding software to ensure all your molding needs are met. Just give us your exact specifications and we'll make your design a reality.

2. Plastic Bucket Mold Manufacturing and Processing

We just need your confirmation and we will utilize our CNC machines to create a very detailed mold prototype for you. We will use this prototype as the main mold for all your products.

3. Plastic Bucket Mold Finishing and Assembly

Once we confirm that you are satisfied with your mold prototype, we will use our injection molding technology to mass produce your barrel products.

9. Our Successfully Delivered Plastic Bucket Mold Case

10. Let's Start Your New Project!

So if you want to efficiently produce competitive plastic drums with good specifications and excellent performance. Leave your request here for quick response, our sales engineer will contact you to discuss plastic bucket mold further.