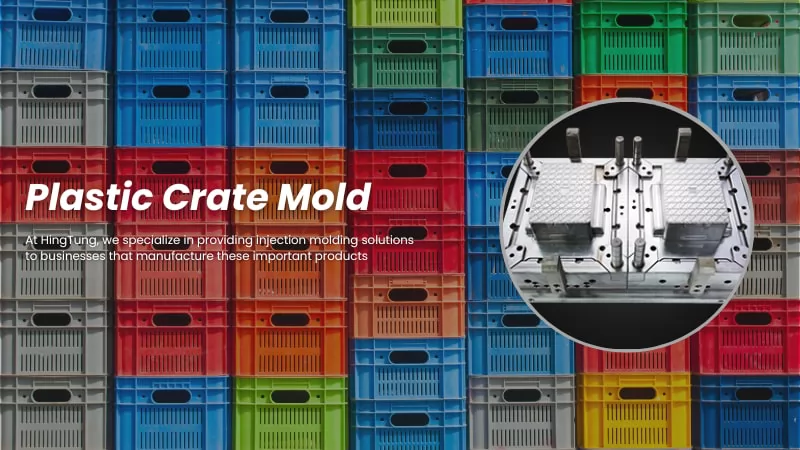

Are you planning to buy new plastic crate molds to start a new business? Hingtung is one of the top plastic crate mold manufacturers and exporters in China. We are committed to providing our customers with the best crate mold products and services, and we strive to always exceed their expectations.

Plastic Crate Design Ability

We are able to design, manufacture and supply your plastic mold requirements regardless of their complexity and or design complexity. Both prototype and crate mould production are done in-house, so we can meet the individual requirements of each project.

Contact Hingtung, we will provide you with the most complete service from plastic crate mold design to production.

Plastic Crate

Plastic Crate

Plastic Crate

Top Plastic Injection Molding Crate and Mold Manufacturer

Hingtung can provide professional plastic crate molds to help you produce plastic turnover boxes efficiently. We provide our customers with full-service solutions that save time and facilitate distribution. That's why Xingtong Mold is committed to providing precision solutions for plastic crate moulds, and eventually becomes a reliable partner to support customers in the plastic crate development and manufacturing process.

Types of plastic crate molds we can produce:

-

Industrial Crate Mold

-

Fish Crate Mold

-

Fruit Crate Mold

-

Vegetable Crate Mold

-

Bread Crate Mold

-

Plastic Milk Crate Mold

What is a plastic crate mold?

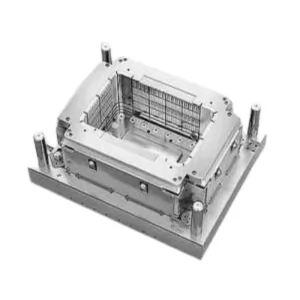

The plastic crate mold is a mold specially used for the production of plastic turnover boxes. A turnover box is a common logistics and storage container, usually made of plastic materials. This type of mold is used in the plastic injection molding process, where molten plastic is injected into the mold, and after cooling and solidification, a molded plastic turnover box is formed.

plastic crate molds are usually made of high-strength metal materials, such as steel or aluminum alloy. The design of the mold is carried out according to the size, shape and structure of the turnover box to ensure that the turnover box that meets the specifications can be obtained during the injection molding process.

These molds play a vital role in the production of plastic crates. The quality of their design directly affects the quality and performance of the final product. High-quality plastic crate molds can ensure the durability, precise size and beautiful appearance of the turnover box.

Due to its lightness, durability and reusability, plastic turnover boxes are widely used in logistics, storage, production and other fields. The use of plastic crate molds makes it possible to mass produce these turnover boxes, providing efficient logistics and storage solutions for various industries.

What is the production process of plastic crate mold?

The production process of plastic crate mold generally includes the following steps:

Design: First, design the mold according to the size, shape and structure requirements of the plastic turnover box. Designers use computer-aided design (CAD) software to draw a three-dimensional model of the mold, taking into account the process requirements for plastic injection molding.

Material preparation: According to the design drawings, select the appropriate mold material, usually use high-strength metal materials, such as steel or aluminum alloy. The material is then cut and machined to prepare the shape and size required to make the mold.

Processing: Use CNC machine tools and other equipment to precisely process mold materials to obtain mold parts that meet design requirements. The processing involves turning, milling, drilling and other processes.

Assembly: Assemble the processed mold parts into a complete mold structure. Ensure the precision and tightness of the fit between mold parts to ensure the stability and precision of the mold.

Heat treatment: In order to improve the hardness and wear resistance of the mold, heat treatment is carried out on the mold. This step can increase the service life and stability of the mold.

Debugging: After the mold is finished, it needs to be debugged. By installing the mold on the injection molding machine, check whether the opening and closing action of the mold is normal, adjust the structure and size of the mold, and ensure the quality of injection molding.

Trial production: After the mold debugging is completed, trial production will be carried out. The molten plastic material is injected into the mold, and the actual production test is carried out to check the molding quality and appearance of the turnover box.

Correction: According to the trial production results, if the product is found to be defective or does not meet the requirements, the mold needs to be corrected and adjusted until the production requirements are met.

Mass production: After the mold debugging and correction are completed, the mold can be put into mass production to produce a large number of plastic turnover boxes.

The production process of plastic crate molds requires the cooperation of experienced engineers and technicians to ensure that the quality and performance of the molds can meet production needs. These finished molds can be recycled on the injection molding machine to efficiently produce plastic crates.

What is the typical service life of a plastic crate mold?

The typical service life of a plastic crate mold depends on many factors, including the material quality of the mold, the manufacturing process, the frequency of use, the characteristics of the injection molding material, and the maintenance of the mold. Generally speaking, the typical service life of a plastic crate mold can range from tens of thousands to hundreds of thousands of injection cycles.

If the mold is made of high-strength, wear-resistant metal materials, and undergoes proper heat treatment and surface treatment, the service life of the mold can usually be improved. In addition, good mold design and manufacturing process are also key factors to ensure the life of the mold.

However, the mold will gradually wear and fatigue during long-term use, especially the surface of the injection cavity inside the mold. As the number of uses increases, the dimensional accuracy and surface finish of the mold may gradually decrease, resulting in a decrease in the quality of injection molding.

In order to prolong the service life of the plastic crate mold, it is necessary to maintain and maintain the mold regularly, clean the surface and cavity of the mold in time, and ensure the normal operation of the mold. In addition, reasonable control of the temperature and pressure during the injection molding process to avoid excessive impact and stress can also help prolong the life of the mold.

Can old plastic containers be recycled or reused?

It is certainly possible to recycle and reuse old plastic totes. Plastic totes are usually made of durable plastic materials so they can be recycled and reused to prolong their life, reduce waste of resources, and lower their impact on the environment.

The process of recycling old plastic totes usually involves the following steps:

Collection: Collect discarded plastic turnover boxes, which can be collected through recycling stations, waste treatment centers, recycling companies or related logistics supply chains.

Classification: Classify and screen the collected plastic turnover boxes, and group them according to material type, size and condition for subsequent processing and reuse.

Cleaning: For turnover boxes with a lot of dirt, they need to be cleaned and disinfected to ensure that they meet the hygienic standards for reuse.

Repair: Some totes may show damage or wear from long-term use and require repair and restoration to restore them to good condition.

Reuse: After cleaning and maintenance, qualified plastic turnover boxes can be put into use again. They can continue to play a role in logistics, warehousing, production, etc., reducing the need to reproduce new turnover boxes.

By recycling and reusing old plastic turnover boxes, it not only contributes to the sustainable use of resources, but also reduces the generation of waste and reduces the burden on the environment. It is an environmentally friendly and economically feasible approach. At the same time, the participation of enterprises and individuals in the recycling and reuse of plastic turnover boxes can also reflect social responsibility and awareness of sustainable development.

What type of material is used for plastic box injection mold?

Plastic box injection molds usually use metal materials with high strength and good wear resistance to ensure the stability and durability of the mold during the injection molding production process. Common plastic box injection mold materials include the following types:

P20: P20 is a commonly used pre-hardened and high-quality tool steel with good cutting performance and high hardenability. It is commonly used in the production of smaller plastic case injection molds.

718: 718 is a heat-resistant, wear-resistant high-quality tool steel that can maintain hardness and stability at higher temperatures. It is suitable for plastic box injection molds with high production requirements or large volume.

H13: H13 is a heat-treated tool steel with excellent heat and wear resistance. It is usually used to produce plastic box injection molds that require high-speed production.

S136: S136 is a stainless steel with excellent corrosion resistance and excellent wear resistance. It is often used in the production of plastic box injection molds that require high mold surface finish.

These materials have different characteristics and scope of application. The mold manufacturer will choose the appropriate mold material according to the specific injection molding production requirements and the design requirements of the plastic box. The selection of appropriate materials can ensure the high durability and stability of plastic box injection molds during long-term use, thereby ensuring the quality and efficiency of injection molding production.

What are the applications of plastic crate molds?

plastic crate molds are widely used in various fields, mainly including the following aspects:

Logistics and warehousing: plastic crate molds are used to produce various specifications and types of plastic turnover boxes, pallets and storage boxes, etc., for logistics, warehousing and cargo transportation, to facilitate the storage, handling and organization of items.

Industrial production: In the industrial production process, plastic crate molds are used to manufacture industrial containers containing raw materials, parts, finished products, etc., providing convenient material management and transportation.

Agriculture: plastic crate molds can be used to produce plastic crates, baskets and containers for agricultural use, which are used to collect, store and transport agricultural products.

Catering and hotel industry: plastic crate molds are used to manufacture food-grade plastic containers and trays, which are suitable for food processing, storage and supply chain management.

Medical and pharmaceutical: In the medical industry, plastic crate molds can be used to produce medical supplies containers, pharmaceutical packaging boxes, etc., for the packaging and storage of medical devices and pharmaceuticals.

Electronic products: plastic crate molds can also be used for packaging and transportation of electronic products, such as electronic components, computer accessories, etc.

Environmental protection: plastic crate molds can be used to manufacture recycling and reused environmental protection boxes, garbage bins, etc., for sorting collection and recycling of waste.

Automobile industry: In the automobile manufacturing process, plastic crate molds are used to produce transportation and packaging of auto parts, providing protection and convenience.

Overall, plastic crate molds play an important role in modern society, providing efficient, convenient and environmentally friendly storage and transportation solutions for various fields.

How to check the mold quality of plastic crate molds?

Checking the quality of plastic crate molds requires careful inspection. Here are some suggested inspection methods:

Appearance inspection: Check whether the surface of the mold is flat and smooth, and whether there are obvious damages, cracks or depressions.

Dimensional inspection: Use measuring tools to check whether the size of the mold meets the design requirements, especially whether the size, angle and structure of the turnover box are accurate.

Matching check: Check the matching of each part of the mold to ensure that there is no looseness or gap between the parts.

Material inspection: confirm whether the materials used in the mold meet the requirements, such as whether the metal materials used are wear-resistant and corrosion-resistant, and whether they can meet the working environment and requirements of the mold.

Injection molding test: Test the mold on the injection molding machine to observe whether the opening and closing of the plastic crate mold is stable, whether the injection molding is smooth, and whether there are defects in the product.

Surface finish inspection: Check that the surface of the injection molded plastic crate is smooth, with no obvious bubbles, marks or scratches.

Confirm the cooling system: Check whether the cooling system of the mold is designed properly and whether the cooling effect is good, so as to avoid deformation or defects during the molding process of the plastic turnover box.

Accuracy inspection: Check the processing accuracy of the mold to ensure that the positioning and processing accuracy of the mold meet the requirements.

Load-bearing capacity test: Carry out a load test on the plastic turnover box to check whether the load-bearing capacity of the turnover box meets the design requirements.

Stacking stability check: Stacking tests are carried out on plastic turnover boxes to ensure that the turnover boxes are stable and not easy to dump when stacked.

Through the above comprehensive inspection, the quality and performance of the plastic crate mold can be effectively evaluated to ensure that the mold can produce high-quality plastic turnover boxes stably and efficiently. At the same time, regular maintenance and maintenance of the mold is also a key measure to ensure the quality and service life of the mold.

How We Can Help You Start Your Plastic Crate Mould Business?

1. Plastic Crate Mould Mold Design

Hingtung has highly advanced molding technology. We utilize the best molding software to ensure all your molding needs are met. Just give us your exact specifications and we'll make your design a reality.

2. Plastic Crate Mould Mold Manufacturing and Processing

We just need your confirmation and we will utilize our CNC machines to create a very detailed mold prototype for you. We will use this prototype as the main mold for all your products.

3. Plastic Crate Mould Mold Finishing and Assembly

Once we confirm that you are satisfied with your mold prototype, we will use our injection molding technology to mass produce your barrel products.

Successfully Delivered Plastic Crate Mould Case

Let's Start Your New Project!

So if you want to efficiently produce competitive plastic crates with good specifications and excellent performance. Leave your request here for a quick response, our sales engineer will contact you to discuss plastic crate mold further.