The global plastic injection molding market reached $187.7 billion in 2022 and should reach $240.9 billion by 2027, with a compound annual growth rate (CAGR) of 5.1% during the forecast period of 2022-2027. It can be seen that the market demand for large plastic molds is still very large. In modern manufacturing, large plastic molds are widely used in various industries, such as automobile manufacturing, electronic equipment, household goods, etc. And in this field, some large plastic mold manufacturers have become industry leaders with their excellent technical strength and rich experience. They not only provide high-quality mold products, but also continue to innovate and promote the development of the industry. In this article, we will highlight several well-known large-scale plastic mold manufacturers list in 2025, and explore their success and impact on the entire industry. It will also answer how to choose a manufacturer or some questions for you.

Report source: bccresearch

Article Directory:

List of top 10 large plastic mold manufacturers in the world

1. Hing Tung

Company Profile:

Shenzhen Xingtong Precision Technology Co., Ltd. was established in December 2011 and is located in Shenzhen, the innovation capital of China. HingTung has been committed to building a high-tech enterprise of design and manufacture. Their product s range from molds , Hardware Products, Plastic Products, Mechanical Equipment, Routers, Set-Top Boxes, Electronic Products, to Gear Technology Development. At the say tim, E, their Business Dimension COVERS DOMESTIC and FOREIGN Trade, Import and Export of Gods and Technology, ETC., ETC. providing customers with a full range of one-stop structural parts services from pre-production inspection, production process control, to rear surface. Handling and pre-assembly is their mission and pursuit.Established: 2011

Headquarters: China

Main Products:

2. Topworks

Company Profile:

Located in Huangyan, Taizhou (a well-known hub for plastic molding), Topworks specializes in providing injection molding and custom mold design services. Their extensive experience in the field has helped them build a strong reputation as one of the top mould manufacturing companies in the world.

Headquarters: China

Main Products:

-

large plastic molds

-

injection molds

-

mold making

3. AMK Plastics

Company Profile:

Founded in 2018, AMK Plastics is a fast-growing injection molding manufacturer in the USA. The company provides comprehensive solutions for the automotive, medical, and consumer goods industries. Their expertise in injection molding has positioned them as a trusted injection molding company in North America.

Established: 2018

Headquarters: USA

Main Products:

-

Automotive Molds

-

Injection Molds

-

Medical Molds

4. JB Tool, Die & Engineering, Inc.

Company Profile:

JB Tool, Die & Engineering, Inc. was founded in 1962. JB Tool started as a company that only designed and manufactured progressive dies, and has grown into a company that designs and manufactures rotary compression molding machinery and tooling, purpose-designed machines for a variety of other businesses, precision machining of parts for the aerospace industry, to suit their Mold making. JB Tool, Die & Engineering currently has close to 65 professional engineers, die makers and machinists ready to meet your machinery, die or precision machined parts needs.

Established:1962

Headquarters: India

Main Products:

-

Blow Mold

-

Injection Mold

-

Mold Manufacturing

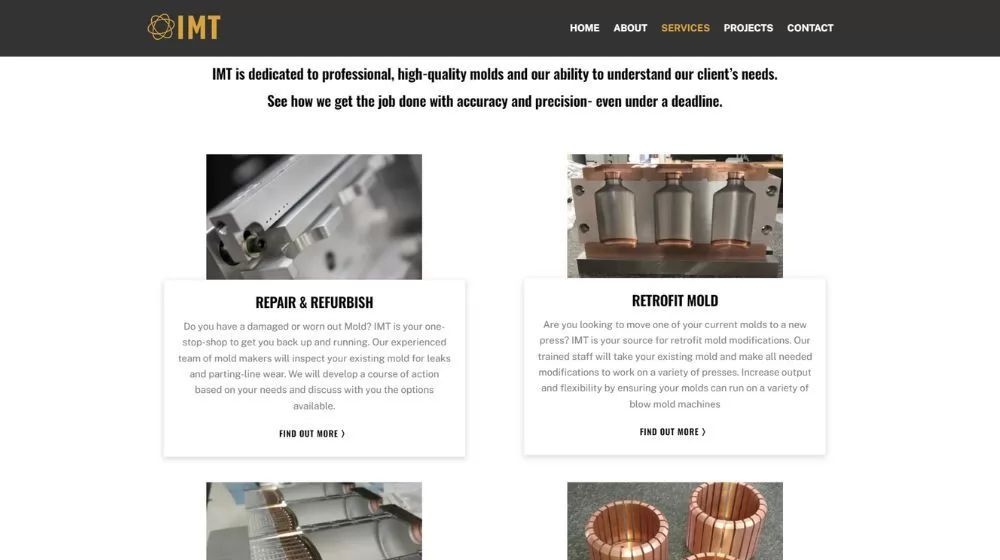

5. Innovation Mold & Tool

Company Profile:

Innovation Mold & Tool, founded in 2015, specializes in plastic injection molding and blow molding for various industries, including packaging and consumer products. Their expertise in injection molding and emphasis on precision has helped them become a respected name among injection molding companies in the US.

Established: 2015

Headquarters: USA

Main Products:

-

Blow Mold

-

Mold Design

-

Mold Main10ance

6. ATMs

Company Profile:

ATM is a leader in the design and manufacture of complex, precision, multi-cavity molds for the plastic injection molding industry. They offer thin-wall, stack-up, hot-runner, twist-off and secondary tooling manufactured using the latest methods and technologies. ATM's unique, mold-friendly approach sets them apart from the competition. They bring you a combination of the best available resources; high-tech equipment, high-quality workmanship, project management and product development techniques that are flexible enough to meet the needs of homogeneous, multi-cavity and multi-mold projects.

Established: 1978

Headquarters: USA

Main Products:

-

mold design

-

mold manufacturing

-

mold management

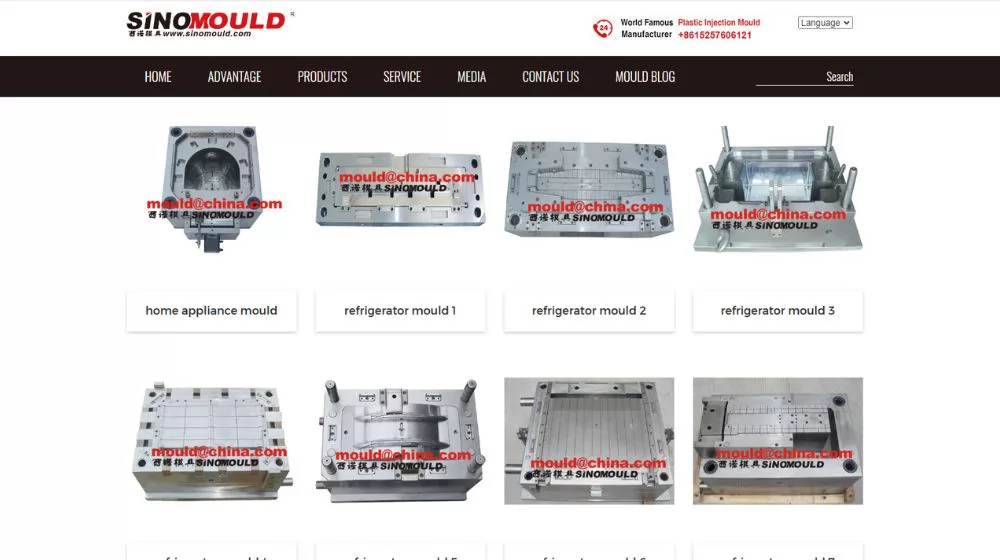

7. SinoMould

Company Profile:

SinoMould has been a dominant player in the injection molding industry for over two decades. Known for their expertise in designing and manufacturing complex plastic molds, SinoMould has earned its place among the top mould manufacturing companies in the world. The company serves industries such as automotive, medical, and consumer goods, delivering high-precision molds at competitive prices.

Established: 1999

Headquarters: China

Main Products:

-

mold design

-

plastic mold

-

medical mold

8. Hanking

Company Profile:

Hanwang Mold was established in 1996 and started plastic injection mold manufacturing business for plastic mold manufacturing and plastic mold parts manufacturing in Longgang, Shenzhen, China. After years of development, they have become a one-stop injection mold manufacturing company integrating mold manufacturing, injection molding, secondary processing and final assembly. As a trustworthy injection mold manufacturing company, Hanwang Mold Engineering Co., Ltd.'s management philosophy is "customer first, quality first". These are guaranteed by their management capabilities, technical know-how, advanced equipment and strict quality standards. The pursuit of high quality and continuous improvement of technical capabilities are their primary goals to meet the ever-demanding market.

Established: 1996

Headquarters: China

Main Products:

-

mold design

-

multi-cavity mold

-

home appliance mold

9. FOW Mold

Company Profile:

FOW Mold is a high-tech enterprise established in 1978 with the mission of providing cost-effective manufacturing solutions. They work closely with customers worldwide to design and manufacture quality molds, industries including barrels, storage, baby products, furniture, home appliances, automotive. With 40 years of experience in the mold manufacturing industry, their business network ex10ds to Europe, America, Russia and other parts of the world.

Established: 1978

Headquarters: China

Main Products:

-

mold design

-

large home appliance mold

-

product design

10. USM

Company Profile:

USM (UNIQUE SOLUTIONS MOLD LIMITED) was established in 2012 and is located in Dongguan City, Guangdong Province, a major mold manufacturing province in China. The factory covers an area of 3,500 square meters and has 85 professional and technical workers with capabilities to manufacture 40 sets of medium-sized plastics per month. 85% of the molds are exported to European and American countries, and it is one of the world's leading manufacturers of plastic injection molding and precision molds. They have been focusing on automated production, high precision, strict requirements, and quality as the soul to manage the factory. All operations are processed in strict accordance with the ISO 9001:2015 standard, which is higher than the requirements of international standards. Strong engineering and design capabilities, and short Leading time and competitive price provide world-renowned companies with high-quality products and services. Professional technology, fast response, reasonable delivery, one-stop service, and exceeding customer expectations are the main factors for USM's success.

Established: 2012

Headquarters: China

Main Products:

-

multi-cavity mold

-

mold manufacturing

-

plastic household mold

Future Market Trends of Large Plastic Molds

The large plastic mold market is seeing continuous growth, driven by advancements in various industries such as automotive manufacturing, electronics, and home appliances. As a result, injection molding manufacturers are witnessing an increase in demand, and injection molding companies are evolving to meet this demand with more innovative solutions. The market is projected to maintain steady growth over the next few years, fueled by technological innovations, industry demand, and the increasing importance of sustainability.

Market Size and Growth

The large plastic mold market is experiencing consistent expansion, especially in sectors like automotive, electronics, and home appliances. The shift towards automation and digitalization, coupled with the growing demand in emerging markets such as Asia-Pacific and Latin America, has contributed to the market's growth. Injection molding manufacturers are adapting to meet the evolving needs of these industries, positioning themselves for continued growth in the coming years.

Industry Competitive Landscape

The competitive landscape in the large plastic mold industry is diverse, with top mould manufacturing companies in the world holding a significant share due to their advanced technological capabilities, rich experience, and global reach. While large manufacturers dominate the industry, there are also small and medium-sized enterprises (SMEs) that specialize in customized and niche services. These smaller players are leveraging their agility and specialized knowledge to carve out their own competitive advantages in the market.

Technological Innovation and Development

Technological advancements play a crucial role in the injection molding company landscape. Manufacturers are increasingly adopting digital design and manufacturing technologies, advanced materials, and intelligent manufacturing processes to enhance production efficiency, reduce costs, and improve product quality. These innovations are not only improving the speed of production but also ensuring that the molds meet the highest standards of precision and durability.

Market Drivers

Several factors are driving the growth of the large plastic mold market:

-

Industry Demand: The automotive, electronics, and home appliance industries continue to experience increasing demand for high-quality plastic molds, fueling growth in the injection molding manufacturer sector.

-

Emerging Market Growth: The demand for large plastic molds in emerging markets is on the rise, especially in regions like Asia-Pacific and Latin America, where manufacturing is growing rapidly.

-

Manufacturing Transformation: As manufacturing processes become more intelligent, efficient, and sustainable, the demand for advanced plastic molds is increasing.

-

Sustainability: Environmental awareness is pushing manufacturers to seek sustainable materials and production processes. This shift towards sustainability is driving the development of eco-friendly molds and production techniques.

-

Automation and Digitalization: The application of automated systems and digital technologies is improving production speed and accuracy, which in turn is accelerating the transformation and upgrading of the industry.

-

Customized Services: To meet specific industry needs, injection molding manufacturers are offering increasingly customized services, providing solutions tailored to different sectors such as medical devices, automotive, and consumer electronics.

Continuous Development Trends

The large plastic mold market will continue to evolve in the following key directions:

-

Sustainability and Eco-Friendly Materials: As the industry becomes more environmentally conscious, manufacturers are focused on using sustainable materials and adopting green manufacturing processes. This trend is expected to drive innovations in mold design and material selection.

-

Smart Manufacturing: The integration of digital technologies and automated manufacturing systems will continue to improve efficiency and reduce costs. Injection molding companies are investing in smart factories and technologies like AI and IoT to enhance production capabilities.

-

Customization: The increasing need for specialized products will lead to a greater focus on custom-designed molds, tailored to meet the specific requirements of various industries, from automotive to medical devices.

How to Find a Good Large Plastic Mold Manufacturer?

Finding a reliable injection molding manufacturer is crucial for ensuring high-quality production. Here are some steps to guide you in identifying a top injection molding company for your needs:

-

Online Search: Start by conducting a thorough search on specialized manufacturer directories and search engines. Filter results based on geographic location, product type, and industry expertise to find manufacturers that meet your needs.

-

Industry Reports and Guides: Refer to industry reports and guides that provide rankings and assessments of plastic mold manufacturers. These evaluations are based on key criteria like market share, technical strength, and quality standards, helping you identify trustworthy companies.

-

Industry Exhibitions and Trade Shows: Attending exhibitions and trade shows is an excellent way to meet injection molding companies in person. These events offer opportunities to network, view product samples, and learn about the latest innovations in the industry.

-

Word-of-Mouth Recommendations: Consult industry experts, supply chain partners, or businesses in the same field for recommendations. Their feedback can provide valuable insights into which manufacturers are most reliable and capable of meeting your specific needs.

-

Company Certifications and Qualifications: Ensure that the manufacturer has relevant certifications such as ISO 9001, ISO 14001, and other quality and environmental management certifications. These qualifications indicate a commitment to maintaining high standards in both production quality and sustainability.

-

Communication and Evaluation: Reach out to potential manufacturers and discuss your project in detail. Ask about their technical capabilities, process flow, quality control measures, and lead times. A thorough evaluation of these aspects will help you determine if they are the right fit for your business.

FAQ

1. Does your company make large plastic molds by yourself?

Yes, we are an experienced manufacturer specializing in large plastic molds with over 10 years of expertise.

2. How many kinds of molds can you make? Do you only make molds?

We produce various types of molds, including injection molds, automotive molds, home appliance molds, and more. We also provide final product manufacturing services.

3. What software will you use to check the drawings?

We use AutoCAD and SolidWorks software for both 2D and 3D drawing evaluations. We accept drawing formats such as PDF, DWG, STP, and IGS.

4. Can you send me free samples?

Yes, we offer free samples; however, customers are responsible for the shipping costs. The shipping fee can be refunded for bulk orders.

5. How to pack the molds and products?

We apply anti-rust oil to the mold, wrap it in plastic film, and then pack it into a fumigation-free wooden box. For products, we use standard export cartons or pack according to customer specifications.

6. I only have samples on hand, can you also make products for me?

Yes, we can create 3D models from samples and assist with product development for mass production.

7. My request at the beginning is small batch, can you help me customize my products?

Yes, we can accommodate small batch orders. As a plastic mold manufacturer, we offer flexibility to meet your needs.

Conclusion

The large plastic mold industry continues to grow, driven by technological advancements, increasing industry demand, and a focus on sustainability. Leading injection molding companies are continuously innovating to stay ahead of market trends, offering cutting-edge solutions and personalized services. By leveraging modern manufacturing processes and embracing digital technologies, these manufacturers are well-positioned to support industries like automotive, electronics, and home appliances with high-quality, efficient mold solutions.

If you are looking for a reliable injection molding manufacturer to meet your needs, companies like HingTung are committed to providing the best service and high-quality products.

You May Be Looking for Other Plastic Molds