We gathered all info new buyers need about Plastic Box Molds. It will help if you want a good custom plastic table mold. We're HingTung, making molds for 10+ years. We used our experience to write this. Happy reading.

We Provide Plastic Table Mold Products

If you're searching for a trustworthy source of plastic table mold products, you've come to the right place. Our expertise lies in delivering premium-grade and cost-effective solutions tailored to suit diverse customers' needs.

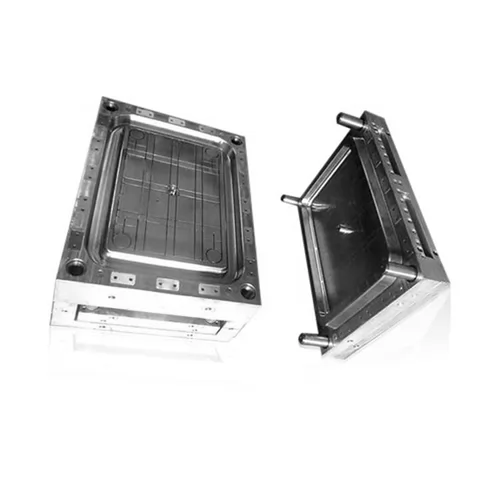

Plastic Table Mold

Plastic Table Mold

Plastic Table Mold

Advantages of Our Plastic Table Mold

Below are the main 4 reasons to choose our plastic table mould.

Customizable design

Our plastic table molds are fully customizable and our cutting edge technology enables us to produce intricate patterns and textures to make your products stand out in the market.

Durable material

Our plastic table molds are made of high-quality materials that can withstand wear and tear. They are built to last, ensuring durability even after frequent use.

Affordable

We offer our Plastic Table Molds at competitive prices, which makes it possible for businesses of all sizes to purchase our mold products without breaking the budget.

Our Process of Making Plastic Table Molds

The manufacturing process of plastic table mold usually includes the following steps:

- Design of the mold: The first step is to create a design for the mold. This scheme includes the shape, size and texture of the mould.

- Material selection: After the design is complete, the next step is to select the appropriate material for the mold.

- Creation of the Mold: Next the mold is created by cutting, forming and assembling the selected materials.

- Testing: Before molds are used to manufacture products, they must be tested to ensure they are working properly.

- Mass production: Once the mold is tested and approved, it can be used for mass production.

- Quality Control: This may include visual inspection, measurement and testing.

FAQs When Purchasing Table Molds

Here are some common questions customers may have when purchasing table models:

What is the lead time for manufacturing table molds?

Lead times for manufacturing table molds can vary depending on factors such as the complexity of the mold design, material availability, and the fabricator's workload. The general delivery time is 15~30 working days.

How do you make sure your table molds are the correct size and shape?

Before a mold is made, the design should be reviewed and approved by the customer to ensure it meets their specifications.

Can table molds be customized to include specific features or textures?

Yes, table top stencils can be customized to include specific features or textures. This can be discussed with the manufacturer during the design phase.

How many products can a table mold produce?

The number of products that can be produced using a single mold depends on factors such as the size of the mold and the manufacturing process used. It is best to consult the manufacturer for an accurate estimate.

Successfully Delivered Plastic Table Mold Mould Case

The Best Plastic Table Mold Manufacturer Around You

We are a professional manufacturer and exporter of Plastic Table Mold in China. We specialize in the manufacture of a wide variety of plastic molds for automotive, appliance, electronics, and general industrial OEM applications.

As an excellent plastic mold manufacturer, we provide custom injection mold design services, plastic mold project management services, plastic mold manufacturing services, mold trial services, quality control plastic injection molding services, semi-finished and finished plastic mold assembly services.

Our production base has been certified by TS16949, ISO 14001 and ISO 9001 etc. You can fully trust our production base, products and placing orders.

You May Be Looking for Other Plastic Molds