PET bottle mold is an important tool for making pet bottles, and PET bottles are a widely used type of plastic bottles. This article will introduce a detailed introduction about pet bottle molds and provide related pet bottle mold manufacturers and market price information and so on.

Article Directory:

What is a PET bottle?

PET bottles are a common type of plastic bottle made of polyethylene terephthalate (Polyethylene Terephthalate). It is widely used in the packaging industry, especially for the packaging of products such as beverages, food, cosmetics and detergents.

What is a PET bottle mold?

PET bottle mold is a mold tool used to make PET bottles. They are made of special metallic materials, such as steel or aluminum, that are precisely designed and constructed so that the desired shape of the PET bottle is molded during the injection molding process. PET bottle mold usually consists of two parts: core mold and cavity mold. The core mold is responsible for forming the inner shape of the bottle, while the cavity mold forms the outer shape of the bottle. By injecting the molten PET material into the mold, and going through the cooling and solidification process, the PET bottle with the desired shape and size can finally be obtained.

What are the types of PET bottle molds?

These different types of PET bottle molds can meet various production needs and make the manufactured PET products more diversified.

Single cavity mold: a mold for making a single PET bottle, suitable for small batch production or sample making.

Multi-cavity mold: including double-cavity, four-cavity, six-cavity and other cavities, which can manufacture multiple PET bottles at the same time and improve production efficiency.

Hot runner mold: Control the injection molding process of PET bottles through the hot runner system to improve the quality and consistency of the bottle mouth and bottom.

Automatic demoulding mold: With automatic demoulding function, the mold can automatically push the PET bottle out of the mold after molding, improving production efficiency.

Horizontal cutting mouth mold: used to manufacture PET bottles with horizontal cutting mouth, suitable for some special needs products.

Adjustable mold: With adjustable design, the capacity and shape of the bottle can be adjusted according to demand.

Market data for PET bottles

According to market research data, the PET bottle market has continued to grow over the past few years, which can be attributed to the following factors.

First of all, PET bottles have many advantages that make them the first choice in the packaging industry. They have good transparency to show the appearance and quality of the product. In addition, PET bottles have a lower weight, which is easy to carry and transport, and also reduces the amount of packaging materials used. PET bottles also have good heat and chemical resistance to maintain product freshness and quality. These properties have made PET bottles increasingly popular in the beverage and food industries.

Second, rising consumer awareness about health and environmental protection is also driving the growth of the PET bottle market. PET bottle material is considered relatively safe and will not release harmful substances. In addition, PET bottles can be recycled and reused, which is in line with the concept of sustainable development. These factors have led many businesses and consumers to opt for PET bottles as a viable alternative to traditional plastic bottles, thereby contributing to the growth in market demand.

According to data from market research institutes, the PET bottle market has maintained a steady growth trend in the past few years. The PET bottle market is expected to continue to be driven by driving factors that are expected to achieve higher growth rates over the next few years. Especially with the development of emerging markets and the continuous improvement of consumers' requirements for quality and convenience, the global demand for PET bottles will further expand.

How to choose a PET bottle mold manufacturer?

Choosing the right PET bottle mold maker is crucial to producing high-quality PET bottles. Here are some reasons to choose a PET bottle mold maker:

1. Experience and expertise

An excellent PET bottle mold maker has rich experience and expertise, and is very familiar with the design and production process of PET bottles. They are able to provide technical support and solutions to ensure the quality and consistency of PET bottles.

2. High quality mold

Excellent manufacturers use high-quality materials and advanced manufacturing techniques to produce PET bottle molds. These molds have good durability and precision, and can be produced stably for a long time.

3. Customization ability

The PET bottle market has diverse and rapidly changing demands. Choosing a manufacturer with customization capabilities can design and manufacture PET bottle molds of specific shapes, sizes and functions according to customer requirements.

4. Delivery time and after-sales service

Manufacturers should be able to deliver molds on time and provide good after-sales service, including maintenance, repair and replacement of molds.

Top five most popular PET bottle mold manufacturers

The following are the top five PET bottle mold manufacturers that are currently widely acclaimed:

1. Hing Tung

Established: 2011

Headquarters: China

Main Products: Mold Design, Mold Manufacturing, Injection Molding, Plastic Mold, Metal Mold, Silicone Mold

Company Profile: Shenzhen Xingtong Precision Technology Co., Ltd. was established in December 2011 and is located in Shenzhen, the innovation capital of China. HingTung has been committed to building a high-tech enterprise of design and manufacture. Their products range from molds, hardware products, plastic products, mechanical equipment, routers, set-top boxes, electronic products, to gear technology development. At the same time, their business dimension covers domestic and foreign trade, import and export of goods and technology, etc., providing customers with a full range of one-stop structural parts services from pre-production inspection, production process control, to rear surface. Handling and pre-assembly is their mission and pursuit.

2.AMK Plastics

Established: 2018

Headquarters: USA

Main Products: Blow Mold, Injection Mold, Filling Mold

COMPANY PROFILE: AMK Plastics was founded in 2018. They supply machines, materials and knowledge to the plastics industry. They offer everything from a small screw to a complete turnkey project. The parent company looks after all their clients in the Far East and Africa, while this office serves their clients in South and Central America and the Caribbean.

3. JB Tool, Die & Engineering, Inc.

Founded: 1962

Headquarters: India

Main Products: Blow Mold, Injection Mold, Mold Manufacturing

COMPANY PROFILE: JB Tool, Die & Engineering, Inc. was founded in 1962. JB Tool started as a company that only designed and manufactured progressive dies, and has grown into a company that designs and manufactures rotary compression molding machinery and tooling, purpose-designed machines for a variety of other businesses, precision machining of parts for the aerospace industry, to suit their Mold making. JB Tool, Die & Engineering currently has close to 65 professional engineers, die makers and machinists ready to meet your machinery, die or precision machined parts needs.

4.Innovation Mold & Tool

Established: 2015

Headquarters: USA

Main Products: Blow Mold, Mold Design, Mold Maintenance

COMPANY PROFILE: Innovation Mold & Tool is a precision machine shop founded in 2015. By the end of 2018, they hired a full-time staff and now specialize in plastic bottle blow molds of all shapes and sizes as well as precision tooling.

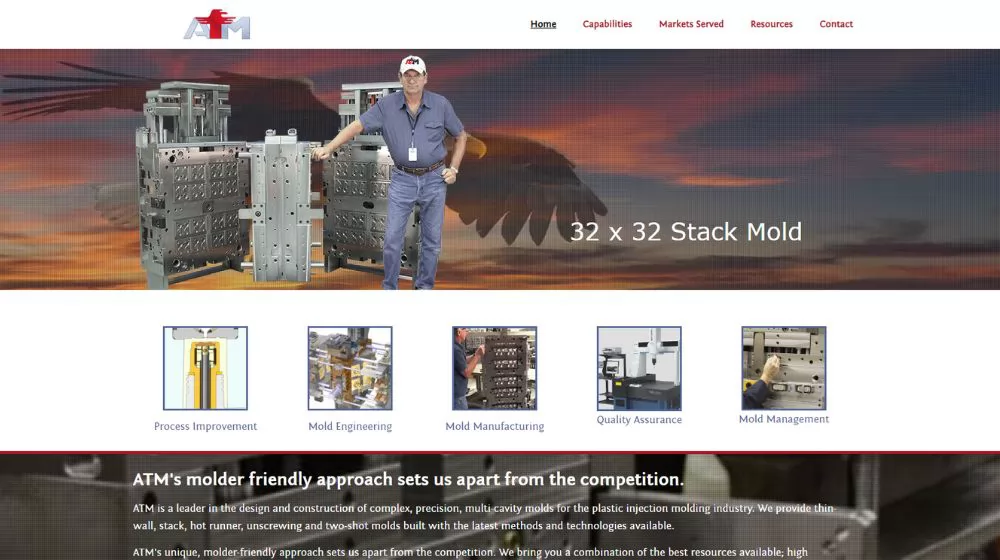

5. ATMs

Founded: 1978

Headquarters: USA

Main products: mold design, mold manufacturing, mold management

COMPANY PROFILE: ATM is a leader in the design and manufacture of complex, precision, multi-cavity molds for the plastic injection molding industry. They offer thin-wall, stack-up, hot-runner, twist-off and secondary tooling manufactured using the latest methods and technologies. ATM's unique, mold-friendly approach sets them apart from the competition. They bring you a combination of the best available resources; high-tech equipment, high-quality workmanship, project management and product development techniques that are flexible enough to meet the needs of homogeneous, multi-cavity and multi-mold projects.

What is the price of PET bottle mold?

The price of a PET bottle mold varies based on a number of factors such as size, shape, complexity, and the manufacturer's brand reputation, among others. Usually, custom-made PET bottle molds are more expensive, while standard size and shape molds are relatively less expensive. The price of a PET bottle mold can range from a few thousand dollars to hundreds of thousands of dollars. When choosing a suitable PET bottle mold, in addition to price, you should also consider aspects such as quality, performance and after-sales service.

Suggestions for choosing a reliable PET bottle mold supplier

To choose a reliable PET bottle mold supplier, consider the following suggestions:

1. Brand reputation

Choose a supplier with a solid brand reputation and industry recognition. Check out their customer feedback and reviews for their credibility and reliability.

2. Quality and performance

Evaluate the quality and performance of samples or existing molds provided by suppliers. Make sure their molds have the durability, precision and productivity they need.

3. Technical support

Suppliers should be able to provide technical support, training and problem resolution. They should have professional engineers and technical team to support your needs.

4. Delivery time and after-sales service

Know the supplier's delivery time and after-sales service commitment. They should be able to deliver molds in a timely manner and provide timely maintenance, repair and replacement services.

Conclusion

In the PET bottle market, choosing the right PET bottle mold maker is crucial for producing high-quality PET bottles. An experienced manufacturer with professional knowledge and a good brand reputation can provide high-quality, customized and reliable PET bottle molds. When selecting a supplier, factors such as price, quality, performance and after-sales service should be considered comprehensively to ensure that the manufacturer finally selected can meet your needs and achieve production goals. If you need, you can contact us, we can provide you with the best PET bottle mold!