With the wide application of plastic cups in the market, small injection molding companies are faced with the challenge of purchasing suitable plastic cup molds. The correct procurement process and selection of the right suppliers are crucial for small injection molding companies. So, how do small injection molding companies purchase plastic cup molds? This article will introduce you some common knowledge of plastic cups and how to buy a good plastic cup mold.

Article Directory:

1.Plastic Cup Mold Manufacturing Process?

2.How to use the plastic cup mold?

3.What are the charateristics of plastic cup mold?

4.What types of plastic cup molds are there?

5.What are the products made with plastic cup molds? What does it apply to?

6.Market demand and market trend of plastic cup mould?

7.What are the key factors to consider when purchasing plastic cup molds?

8.How to buy a good plastic cup mold in China?

9.What is the after-sales service of the molds bought in China?

10.Summarize

Plastic Cup Mold Manufacturing Process?

Design and formulate specifications: First, design the mold and formulate specifications according to the size, shape and design requirements of the plastic cups to be produced. This step is usually done by a professional designer.

Making mold core and mold cavity: According to the design requirements, metal materials (such as steel, aluminum alloy, etc.) are used to make mold core and mold cavity. The mold core is the inner shape of the plastic cup, while the mold cavity is the outer shape.

CNC processing: through computer numerical control (CNC) processing equipment, metal materials are precisely cut and processed to obtain mold cores and mold cavities that meet the design requirements.

Assembling the mold: Assemble the mold core and mold cavity, usually fixed together with bolts, fasteners, etc., to ensure the stability and accuracy of the mold.

Surface treatment: Treat the surface of the mold, such as grinding, polishing, electroplating, etc., to improve the smoothness and durability of the mold.

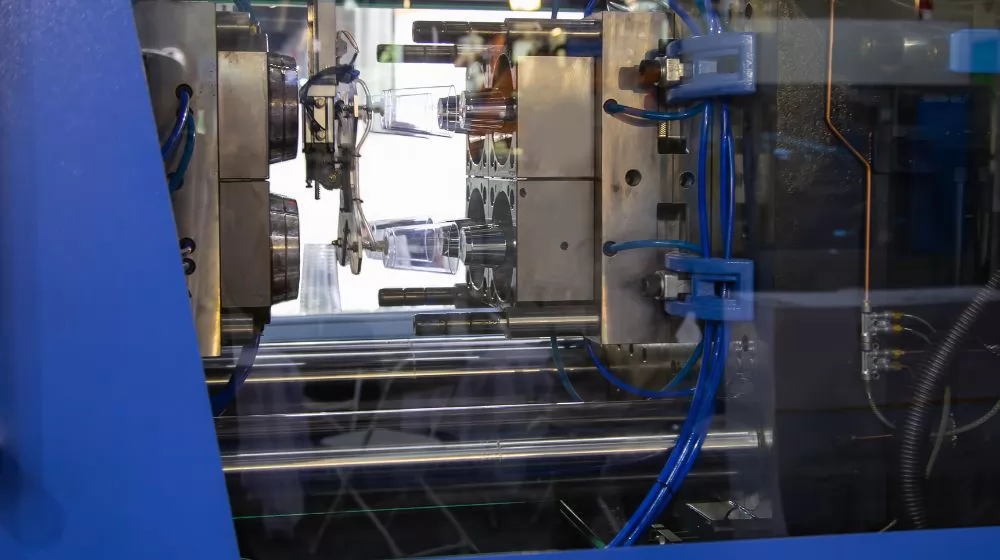

Commissioning and testing: Install the assembled and processed molds on the injection molding machine for commissioning and testing. Inject the plastic through the injection molding machine, check the operation of the mold and the effect of the injection molding, and make minor adjustments and corrections if necessary.

Production of plastic cups: After the mold debugging is completed, the mold can be used for mass production of plastic cups. The plastic material is heated and melted and injected into the mold. After cooling and solidifying, the formed plastic cup is taken out.

How to use the plastic cup mold?

Prepare the mold: Make sure the plastic cup mold is clean and free of impurities, and check that the mold is intact.

Install the mold: Install the mold on the injection molding machine, make sure the mold is stable and correctly aligned.

Prepare raw materials: choose suitable plastic material, cut it into proper size and put it into the hopper of injection molding machine.

Adjust the parameters of the injection molding machine: According to the requirements of the plastic cup mold, adjust the parameters of the injection molding machine, such as temperature, injection speed, injection pressure, etc.

Start injection molding: Start the injection molding machine and let it work according to the set parameters. The plastic material is heated to melt and injected into the mold through an injection system.

Wait for cooling: After the plastic has fully filled the mold cavity, wait for a period of time for the plastic to cool and solidify.

Take out the finished product: open the mold and take out the injection molded plastic cup. If the mold is a multi-cavity design, multiple plastic cups can be taken out at one time.

Inspection and trimming: Check whether the taken out plastic cups meet the quality requirements, and if necessary, trim and deburr them.

Repeated production: Repeat the above steps as needed to continue to produce more plastic cups.

What are the characteristics of plastic cup mold?

Highly customizable: Plastic cup molds can be individually designed and customized according to needs to meet the production of plastic cups with different shapes, sizes and design requirements.

Efficient production: The use of plastic cup molds can be used for high-volume and high-efficiency production. The injection molding machine combined with the working mode of the mold can complete the injection molding process in a short period of time and improve production efficiency.

Reusable: Plastic cup molds are usually made of durable metal materials, which have a long service life. The mold made once can be used repeatedly, which reduces the production cost.

High precision: Advanced processing technology is used in the mold manufacturing process to ensure the high precision and accuracy of the mold. This enables plastic cup molds to produce plastic cup products with regular shapes and consistent sizes.

Strong scalability: The design of the plastic cup mold can be adjusted and changed according to market demand. If it is necessary to produce plastic cups of different shapes or sizes, the mold can be modified or redesigned to meet different production needs.

Economy: Compared with the manufacturing process of other materials, the manufacturing cost of plastic cup mold is relatively low. Once the mold is made, the cost in the production process is relatively low, which is suitable for large-scale plastic cup production.

What types of plastic cup molds are there?

|

Mold Type |

Describe |

|

Single Cavity Mold |

The mold can only produce one plastic cup at a time. |

|

Multi-Cavity Mold |

A mold that can produce multiple plastic cups of the same shape and size at one time. |

|

Flip Mold |

Molds for plastic cups with flip lids can be produced, and the cup body and lid are made by one-time injection molding. |

|

Handle Mold |

A mold suitable for the production of plastic cups with handles to make the cups easier to use. |

|

Stack Mold |

Molds for plastic cups with stackable features can be produced for easy storage and transport. |

|

Printing Mold |

Equipped with printing equipment, it can print patterns or words on plastic cups. |

|

multilayer mold |

Molds that can produce multi-layer plastic cups, such as thermos cups, etc. |

|

custom mold |

Custom designed molds for specific needs can produce plastic cups with unique shapes or functions. |

What are the products made with plastic cup molds? What does it apply to?

|

Product |

Describe |

Applicable Aspects |

|

Disposable plastic cup |

Used for one-time beverage consumption, such as cold drink cups, hot drink cups, milk tea cups, etc. |

Catering industry, fast food restaurants, coffee shops, beverage shops, etc. |

|

Plastic cup |

Used to hold cold water, mineral water, fruit juice and other beverages. |

Home, office, school, outdoor activities, etc. |

|

Plastic coffee cup |

For hot coffee, tea and other hot beverages. |

Coffee shop, beverage shop, office, fast food restaurant, etc. |

|

Plastic sports water bottle |

Lightweight, durable plastic water bottle for outdoor sports and fitness activities. |

Gym, outdoor sports, camping, travel, etc. |

|

Plastic cup tray |

Trays for collecting and transporting plastic cups for easy storage and distribution. |

Catering industry, supermarket, logistics and transportation, etc. |

|

Plastic cup sleeve/Protective sleeve |

Used to wrap plastic cups, provide heat preservation and anti-slip functions, and prevent hand burns. |

Coffee shops, restaurants, takeaway services, etc. |

|

Plastic cup lid/Straw lid |

Lids for plastic cups, including regular lids and lids with straw spouts. |

Beverage store, fast food restaurant, takeaway service, etc. |

|

Plastic cup ornament/Gift |

Decorations or gifts made of plastic cups, such as printed patterns, personalized customization, etc. |

Holiday gifts, corporate promotions, event souvenirs, etc. |

|

Plastic cup storage box |

A storage box designed with a plastic cup combined with a lid, which can be used to store small items and food. |

Home, office, student dormitory, kitchen, etc. |

|

Plastic cup art |

Artworks created using plastic cups, such as sculptures, installation art, etc. |

Art exhibition, art decoration, museum, etc. |

Market demand and market trend of plastic cup mould?

Market Demand:

Wide application of plastic cups: As a key tool for the production of plastic cups, plastic cup molds are driven by the needs of the plastic cup manufacturing industry. Plastic cups are widely used in homes, restaurants, cafes, fast food restaurants, hotels and other places to meet people's needs for drinks and liquid food.

Increased demand for personalization: Consumers are increasingly demanding personalized and uniquely designed plastic cups. This prompts plastic cup manufacturers to continuously update mold designs to produce attractive, creative and personalized plastic cups to meet the diverse needs of consumers.

Growth in demand for customization: Many businesses, brands and events require customized plastic cups for publicity and promotional purposes. This has led to an increase in the market's demand for customized plastic cup molds to meet the specific needs of companies and brands.

Market Trend:

Advances in manufacturing technology: With the continuous development of science and technology, the manufacturing technology of plastic cup molds is also improving. High-precision CNC machine tools, advanced mold design software and the application of new materials make the production of plastic cup molds more efficient, accurate and stable.

Enhancement of environmental protection awareness: With the improvement of environmental protection awareness, the market demand for degradable plastic cup molds is gradually increasing. Plastic cup molds made of degradable materials can reduce the negative impact on the environment and meet consumers' pursuit of environmentally friendly products.

Development of automated production: The application of automation technology in the field of plastic cup mold production continues to improve. The automated production line can improve production efficiency and reduce labor costs, making the production of plastic cup molds faster and more accurate.

The trend of personalized customization: With the rise of personalized consumption, the market demand for personalized customized plastic cup molds is on the rise. Manufacturers of plastic cup molds need to respond flexibly and be able to provide customized design and production capabilities to meet the individual needs of customers.

What are the key factors to consider when purchasing plastic cup molds?

Quality and durability: Choose a high-quality plastic cup mold to ensure its manufacturing quality and durability. High-quality mold materials and manufacturing processes can provide longer service life and better mold performance.

Mold size and capacity: According to the required plastic cup size and capacity, select the corresponding mold size. Make sure the mold is capable of producing the desired plastic cup size.

Design and customization capabilities: If you need to customize plastic cups with special shapes, designs or functions, choose suppliers with design and customization capabilities that can meet individual needs.

Production capacity and efficiency: Consider the supplier's production capacity and efficiency, including mold production cycle, delivery time and production capacity, to ensure that the expected production demand can be met.

Technical support and after-sales service: Choose a supplier that provides good technical support and after-sales service, and can provide necessary training, maintenance and technical support to ensure the normal operation and maintenance of the mold.

Price and cost-effectiveness: comprehensively consider the price and cost-effectiveness of the mold, choose a reasonable price range, and be able to provide cost-effective plastic cup molds.

Supplier reputation and experience: Choose a reputable and experienced supplier who can provide stable and reliable products and services to ensure the quality and delivery reliability of the purchased plastic cup molds.

How to buy a good plastic cup mold in China?

Market research: Conduct research on China's plastic cup mold market to understand the situation of each supplier, including product quality, reputation, experience, technical capabilities, etc. Information can be obtained through Internet searches, participation in industry exhibitions, and consultation with industry insiders.

Supplier screening: According to the market research results, select several suppliers with good reputation and experience, and further understand their product quality, production capacity, technical support, after-sales service and other aspects.

Sample Evaluation: Request plastic cup mold samples from selected suppliers for evaluation. Carefully check the sample for manufacturing quality, detail handling, dimensional accuracy, etc., and compare with expected requirements.

Factory visit: If possible, arrange to visit the supplier's production factory. Through on-the-spot inspection, understand their production equipment, production process, quality control system, etc., to further evaluate the strength and production capacity of suppliers.

Communicate with suppliers: communicate fully with selected suppliers to learn more about their technical support capabilities, after-sales service, delivery time, price and cooperation terms, etc. Ensure smooth communication between the two parties and clarify the details of cooperation.

Reference customer evaluation: To understand the supplier's customer evaluation and feedback, you can communicate with other customers or view the supplier's reference customer list to understand their satisfaction and cooperation experience.

Contract signing: After confirming the selected supplier, sign a contract with it. Make sure that the contract clearly stipulates important terms such as product specifications, quantity, price, delivery time, and after-sales service to ensure the rights and interests of both parties.

Through the above steps, you can buy good quality and reliable plastic cup molds in China, and establish long-term cooperative relationships with plastic cup mold manufacturers to provide stable support for plastic cup production.

What is the after-sales service of the molds bought in China?

Technical support: The supplier will provide relevant technical support, including assistance in mold installation and commissioning, operation guidance, maintenance, etc. They can answer the problems you encounter in the process of using the mould, and provide solutions and suggestions.

After-sales maintenance: If the mold breaks down or needs to be repaired during use, the supplier will provide corresponding after-sales maintenance services. They can send professional technicians to on-site repairs, or provide repair guidance and parts support to ensure that the mold can run normally.

Spare parts supply: If the spare parts of the mold need to be replaced, the supplier will provide corresponding spare parts supply services. They can provide original spare parts according to your needs to ensure the normal operation and maintenance of the mold.

Training service: The supplier can provide corresponding training for your operators so that they can operate and maintain the mold correctly. The training content can include the knowledge of the safe use of molds, operating procedures, common troubleshooting, etc., to improve the skills and efficiency of operators.

After-sales feedback and improvement: Suppliers usually conduct after-sales feedback and communication with customers on a regular basis to understand the use of molds and customer feedback. They will improve and optimize according to customer feedback and needs to improve the quality and performance of the mold.

Summarize

In conclusion, purchasing plastic cup molds is a key decision for small injection molding companies. By understanding their own needs, choosing experienced and reputable suppliers, focusing on price and cost performance, emphasizing after-sales service, and establishing long-term cooperative relationships, small injection molding companies can obtain high-quality plastic cup molds and provide customers with high-quality products.

Considering the wide application of plastic cups and the multiple benefits they bring, you may be interested in using plastic cup molds. At HingTung, we are committed to meeting your plastic cup mold needs and providing you with excellent service. We are proud to be able to provide customers with product design and model design support, at the same time, we also provide metal molds, plastic molds and silicone molds to meet your various needs. If you are interested in working with us or would like to know more about the services we can provide, please contact us immediately.