In the world of injection molding, two common types of molds are frequently used: the two plate mold and the three plate mold. Both serve the same basic function—producing molded plastic parts—but they differ significantly in their design, functionality, and the types of products they produce. In this article, we will explore the 2 plate mold and 3 plate mold difference and help you determine which one is most suitable for your needs.

List of Contents |

|

|

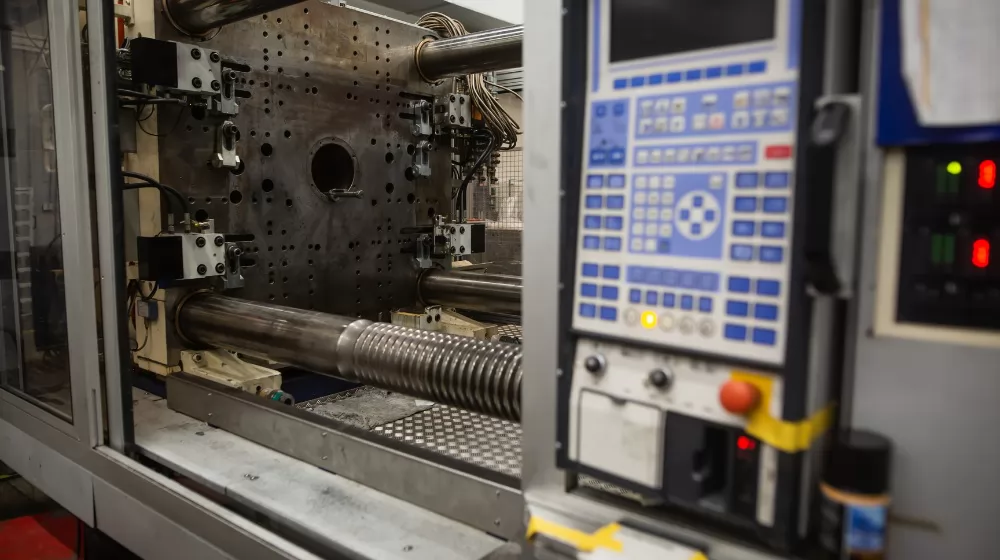

What Is a Two-Plate Mold?

A two plate mold is a straightforward and widely used injection mold type, typically consisting of two main plates: the cavity plate and the core plate. These plates work together to form the shape of the part being molded. The cavity plate contains the cavity that shapes the exterior of the part, while the core plate forms the internal features.

How Does Two Plate Mold Works?

-

Injection: Molten plastic is injected into the mold cavity through the sprue, which is aligned with the parting line. The plastic flows through runners and gates to fill the cavity.

-

Cooling: Once the cavity is filled, the plastic cools and solidifies within the mold.

-

Opening: The mold then opens along the parting line. The stationary A-side remains fixed, while the movable B-side retracts, pulling the solidified part along with the runners and sprue attached.

-

Ejection: Ejector pins on the B-side push the solidified part out of the mold. After ejection, the mold closes again, and the cycle repeats.

Advantages of Two-Plate Mold

-

Simple Design: A two plate mold is easy to design, operate, and maintain. Its simplicity makes it ideal for small production runs and cost-sensitive projects.

-

Cost-Effective: Two plate molds are generally less expensive compared to three plate molds, making them the go-to choice for manufacturers on a tight budget.

-

Lower Maintenance Needs: The fewer parts and simpler design mean less maintenance and fewer opportunities for failure.

Limitations of Two-Plate Mold

-

Limited Part Complexity: A two plate mold is best suited for simple parts without undercuts or complex features.

-

Longer Cycle Times for Multi-Cavity Molds: When producing multiple cavities, the cycle time may be longer, as each cavity needs to be filled individually.

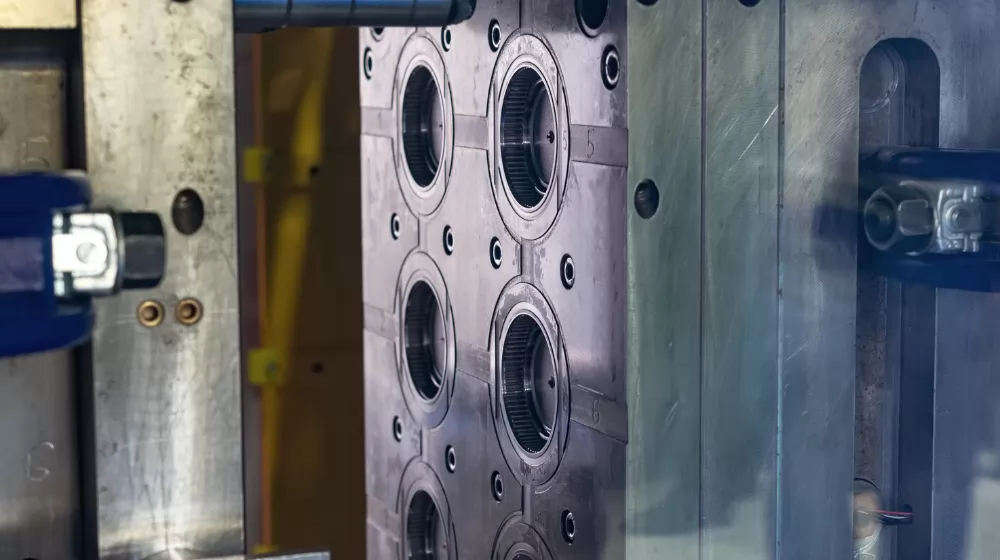

What Is a Three-Plate Mold?

The 3-plate mold, often known as a "double parting surface mold," offers versatile functionality in injection molding processes. It incorporates a runner stripper plate placed between the top clamping plate and the cavity plate, creating a three-part mold assembly. This type of mold is typically used when the part is too large for a two-plate mold or when multiple injection points are required. The design of the three-plate mold allows for better positioning of the gate, making it ideal for products that cannot have gate marks on their sidewalls or those with significant projection areas that need multiple point gates.

A key characteristic of this mold design is the inclusion of a smaller gate, which is essential for products with complex geometries. Due to its intricate design, this mold type requires an additional distance parting mechanism. There are two variations of the three-plate mold: the standard version and the simplified version. The simplified mold, unlike its more complex four-plate counterpart, uses only two guide pins to separate the two halves.

How Does Three Plate Mold Works?

-

Injection: Similar to the two-plate mold, molten plastic is injected into the mold. However, the runner system is located on the runner plate, allowing for more flexible gate placement.

-

Cooling: The plastic cools and solidifies within the mold cavity.

-

First Opening: The mold first opens between the runner plate and the cavity plate, separating the runner from the molded part.

-

Second Opening: The mold then opens between the cavity plate and the core plate, allowing the molded part to be ejected by ejector pins on the core plate.

-

Ejection: The final part is ejected from the mold, while the runner is automatically separated and ejected separately.

Advantages of Three-Plate Mold

-

Increased Part Complexity: A three plate mold can create parts with intricate features, including undercuts and hollow structures, thanks to the third plate.

-

Shorter Cycle Times for Multi-Cavity Molds: The separation of runners from the part improves cycle times for multi-cavity molds, making them more efficient for large production runs.

-

Sprue Elimination: With a three plate mold, the sprue can be separated from the part, improving part quality and reducing post-processing.

Limitations of Three-Plate Mold

-

More Complex Design and Operation: The design and operation of a three plate mold are more complicated, requiring higher expertise.

-

Higher Costs: The additional plate increases the cost of manufacturing and maintenance.

-

More Maintenance: The increased complexity results in more parts that need maintenance.

Key Differences Between Two Plate Mold and Three Plate Mold

Table: Difference of Two Plate Mold and Three Plate Mold

| Feature | Two Plate Mold | Three Plate Mold |

|---|---|---|

| Number of Plates | Two | Three |

| Part Complexity | Limited | Increased |

| Cycle Time for Multi-Cavity Molds | Longer | Shorter |

| Ability to eliminate sprue from part | No | Yes |

| Cost | Less expensive | More expensive |

| Maintenance | Requires less | Requires more |

| Mold Making Process | Simpler | More complex |

| Common Applications | Toys, electronic housings | Automotive, medical, consumer goods |

Which Mold Should You Choose?

When faced with the decision between a two plate mold and a three plate mold, there are various factors that should be taken into account. These factors encompass the intricacy of the part, the number of parts needed, the budget, and the time frame.

If the part requires intricate shapes or features, a 3 plate mold may be the superior option. In terms of the quantity of parts required, a two plate mold may be more cost-efficient for lower quantities, while a three plate mold may be more favorable for higher quantities, as it can produce shorter cycle times and lower unit costs.

Regarding budget constraints, 2 plate mold generally offer more cost-effective solutions, and may be the preferred choice for smaller budgets. However, for intricate parts or high quantities, a three plate mold may be a worthwhile investment.

If time is of the essence, a two plate injection mold may be the better option, as it usually has shorter lead times compared to a three plate mold. Taking these factors into consideration, an informed decision can be made about which mold type is the most suitable for a given project.

Applications of Two Plate Mold vs Three Plate Mold

Both molds are used across various industries, but their applications differ based on complexity and production volume:

Two Plate Mold Applications

-

Consumer Goods: Toys, containers, household items.

-

Automotive: Interior panels, dashboards, and trim.

-

Medical: Basic medical devices and instruments.

-

Electronics: Housings for computers, cell phones, etc.

Three Plate Mold Applications

-

Automotive: Complex interior and exterior parts like bumpers and headlights.

-

Medical: Devices requiring precision and complex geometries.

-

Aerospace: Parts with stringent tolerances and intricate features.

-

Packaging: Thin-walled containers and high-accuracy packaging components.

Differences in Mold Making Process

The procedure for constructing a mold can vary based on whether it is a two plate mold or a three plate mold. In a two plate mold, the two halves of the mold converge to form the mold cavity, which is then opened to extract the component, repeating the process. On the other hand, a three plate mold has an additional plate known as the runner plate, which isolates the sprue from the component. Consequently, the runner plate can move autonomously, allowing the sprue to be detached from the component during the ejection process.

The mold creation procedure for a two plate mold is less complicated than that of a three plate mold since there are fewer plates required. Nevertheless, the mold's intricacy and the number of cavities required can impact the mold creation process for both types of molds.

When fabricating a two plate mold, the mold designer must consider the parting line and the ejector pin's location. In comparison, for a three plate mold, the designer must consider the runner system and gating's position. The gating and runner system's design is critical for a three plate mold since it can influence the part's quality and appearance.

Overall, the mold creation process for a three plate mold is more intricate than that of a two plate mold. This augmented complexity can lead to increased costs and longer lead times. However, the capability to segregate the sprue from the component during ejection can result in higher quality parts and lower scrap rates.

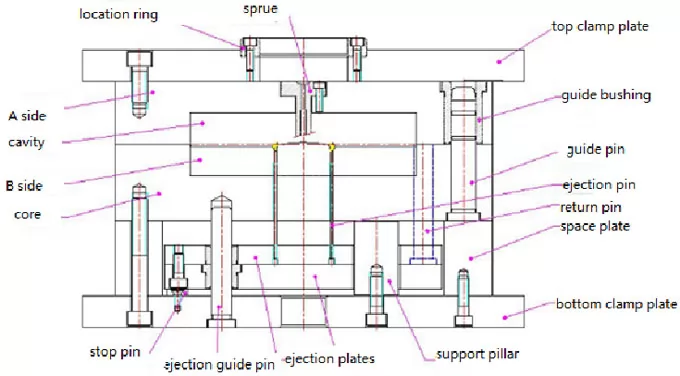

Main Components of Two-Plate Mold

A two-plate mold is a straightforward and commonly used design in injection molding, consisting primarily of two halves: the stationary half (A side) and the moving half (B side). Here are its key components:

-

Mold Base: The foundation that supports and holds all other components together.

-

Cavity and Core: The cavity (A side) shapes the external features of the part, while the core (B side) forms the internal features.

-

Ejector Pins: These are located in the core side and push the finished part out of the mold after it solidifies.

-

Sprue and Runner System: Channels through which the molten plastic flows from the injection machine nozzle to the mold cavities.

-

Guide Pins and Bushings: Ensure precise alignment between the two halves of the mold.

-

Cooling System: Comprises channels within the mold to circulate cooling fluid, helping to solidify the molten plastic efficiently.

-

Vent System: Allows trapped air and gases to escape, preventing defects in the final part.

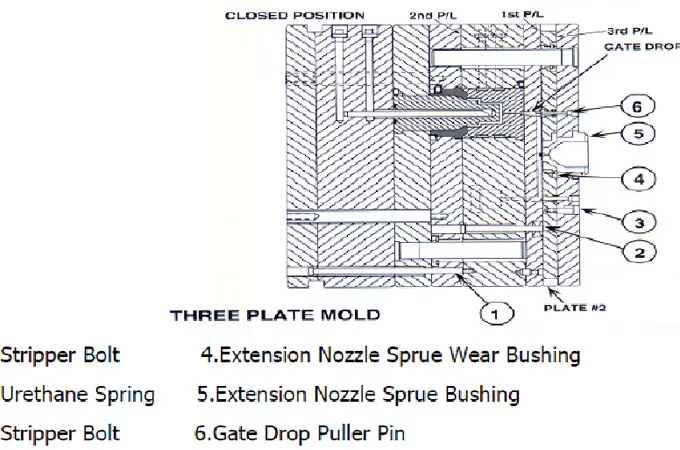

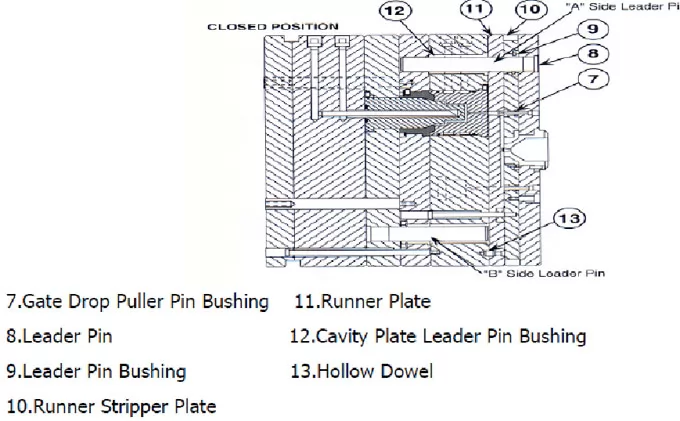

Main Components of Three-Plate Mold

-

Mold Base: Similar to the two-plate mold, providing structural support.

-

Cavity Plate, Core Plate, and Runner Stripper Plate: The three plates are arranged to allow the separation of the runner and parts at different points in the mold opening sequence.

-

Ejector Pins: Used to push the molded parts out of the cavity once the plastic has cooled and solidified.

-

Sprue and Runner System: Delivers molten plastic from the injection machine to the mold cavities, with the runner system often designed to be separated by the stripper plate.

-

Guide Pins and Bushings: Ensure the alignment of the plates during mold opening and closing.

-

Cooling System: Includes channels for fluid circulation to maintain consistent mold temperatures and improve part quality.

-

Vent System: Channels or slots to allow air and gases to escape, avoiding defects in the parts.

-

Return Pins: Ensure the plates return to their original positions after each cycle.

Conclusion

Both two plate molds and three plate molds are integral to the injection molding process, but they serve different purposes based on the complexity of the part being produced. Two plate molds are simple, cost-effective, and ideal for producing basic parts. In contrast, three plate molds are better suited for complex parts that require more precision and design flexibility. By understanding the differences and advantages of each mold type, you can choose the right one to meet your production needs.

If you need injection molding service from China or want to know more details, please feel free to contact us, we are the leading plastic mold manufacturer in China, Hing Tung, working with Hing Tung can help you to solve all the problems encountered in the process of injection molding, and the finished products that we injection molded will surely satisfy you.

Relate Read Recommandation: